tooln

5 year old buck +

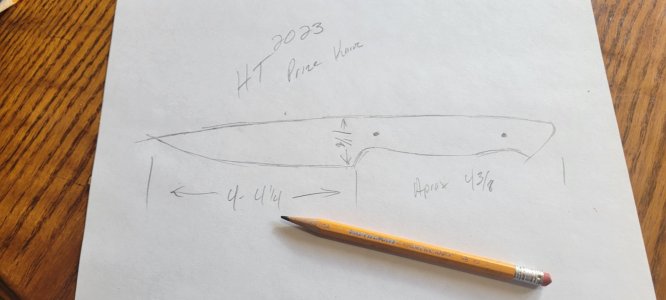

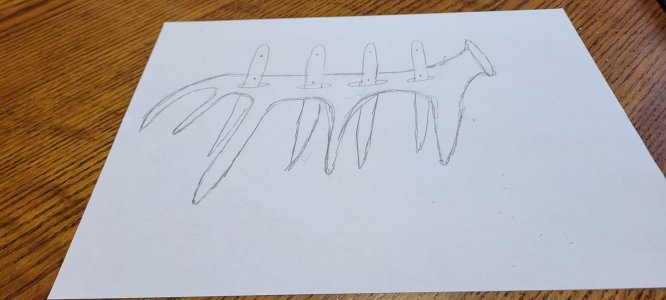

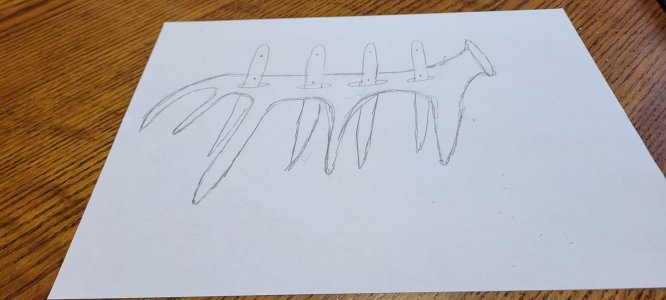

I haven't forgotten about the prize knife I've just been so busy with life events. I've been giving a lot of thought of what to build as I want to make it very special. I think I've finally come up with what I want to make for you guys. Your going to have to excuse the rough sketch as I can't draw to save my ass, but I think you'll get the idea. It will be a set of 4 stainless steak knives, each with a different wood as handle material. I'm going to used a shed antler as a holder/display. I'm hoping to start the build in the next few weeks. So stay tuned and I'll post some updates along the way. Get your entries in.

Last edited:

Sure way to win!

Sure way to win!