tooln

5 year old buck +

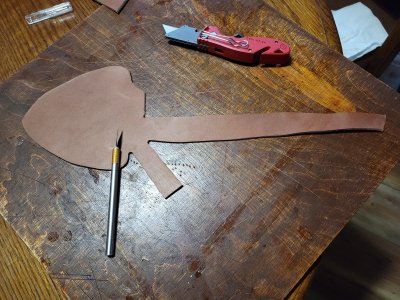

This weeks update shows the the bevel has been ground into the blade. I also dimpled some holes to hold some epoxy to help hold the handle scales on. Don't forget to enter it could be yours.

https://habitat-talk.com/threads/habitat-talks-september-trail-cam-contest.14890/#post-291106

https://habitat-talk.com/threads/habitat-talks-september-trail-cam-contest.14890/#post-291106