-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HT 2024 trail cam contest prize build

- Thread starter tooln

- Start date

tooln

5 year old buck +

Did some profiling and hand sanding on the handle today. I'm up to 400 grit, it's starting to come around. I'll have to get up over 1000 grit to get it to pop. I have one side of the handle with the sea shells towards the top, the other side, the bottom. Each side of the handle will have its own look. Once I get into the finer grits, the side with the sea shells towards the bottom will come around. Picture don't do it justice right now.

Attachments

Howboutthemdawgs

5 year old buck +

Geez gorgeous! True talentOk I'm back at the prize knife. Hand sanded to 1500 grit. Pictures don't do it justice. Once I wax and polish it will be even better. View attachment 67530View attachment 67531View attachment 67532

tooln

5 year old buck +

Today I finished up the Fillet prize knife. To recap it has a stainless blade .040 thick which makes it very flexible. The handle has seashells embedded in a clear epoxy with stainless pins. One side has the seashells towards the top and the other near the bottom. This was done intentionally to give it an unique look. The sheath has finished leather both inside and outside. The display is a piece of spalted maple. If you want a chance to win this you have to enter. I do have to say the pictures don't do it justice, but I do say that a lot. The other knife to be included in the contest is a cleaver. I'll start on that sometime in the next few months.

tooln

5 year old buck +

tooln

5 year old buck +

Bill likes me to space out the updates of the build. I'll try my best to space them out but afraid I'll miss something along the way. Normally I work on it and set it aside come back later to do something then post an update. I'm swamped with orders to get done for Christmas and need to get the cleaver finished so it's not forgotten. Here's what the display for it will be. Don't forget to get your trail cam pics in for a chance to win.

tooln

5 year old buck +

Well the something special I had planned for the handle didn't go as planned. I had some deer teeth & antler pieces imbedded in clear epoxy. While surface sanding one dropped and cracked so it not large enough to use. So I picked out a nice piece of olive wood. This came from Bethlehem and is complete with a COA. I've made a few handles from this and once I get it sanded it really comes to life. Don't forget to enter if you want a chance if winning.

tooln

5 year old buck +

It's going to take some time but I'll get it figured out. These are t bad for first time using it

Post in thread 'Tool'n Knife Builds' https://habitat-talk.com/threads/tooln-knife-builds.14122/post-359407

Post in thread 'Tool'n Knife Builds' https://habitat-talk.com/threads/tooln-knife-builds.14122/post-359407

tooln

5 year old buck +

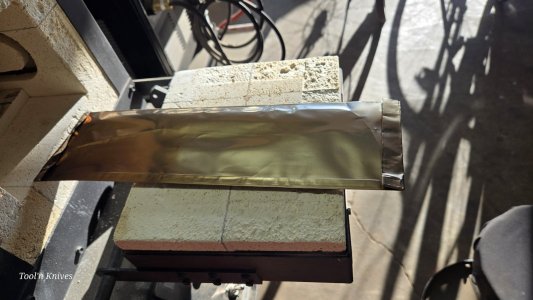

Well both prize knives are done. I’m just going to give a little recap on each. The fillet has a .040 thick blade and the cleavers is .160. Both are made from 14c28n Stainless which is a Swedish Stainless used in high end cutlery. The displays are each made from spalted maple with the cleavers having a live edge. The bobbers for the fillet will need to be put in as they will be removed for shipping, be careful as it is a tight fit. The handle for the fillet is a clear epoxy embedded with sea shells. Each side of the knife has a different look with one side has the shell towards the top and the other towards the bottom. This gives a unique look, the pins are also Stainless. The fillet has a sheath with finished leather on the inside as well as outside. The Cleaver has mosaic pins one being a bucks head the other a bear claw. The epoxy I use is the best money can buy. No cheap 5-minute stuff for me. It is water proof, UV resistant has a modulus elasticity of 150,000 psi & tensile strength of 3,440 psi. The handle is olive wood direct from Bethlehem complete with a COA, this takes over a month to get shipped to me. Shipping in or out through customs is a royal PITA. With proper care these can be a family heirloom. I’ll be posting pics of both knives soon. The edge retention test for the cleaver video will be Monday. I've had people say that Olive wood can be gotten in the states. Well here's my proof.

Howboutthemdawgs

5 year old buck +

Yeah, unreal. You are so talented.

tooln

5 year old buck +

Thanks. I just got lucky and found something I really like doing. Just ended up being good at it. I never figured I'd be so busy during retirement. By the end of the year I'll be at over 200 made. 14 different states and the possibility of 1 going out of the country.Yeah, unreal. You are so talented.

Howboutthemdawgs

5 year old buck +

That’s great! Though I have a feeling you have many talents and this is just an extension of thoseThanks. I just got lucky and found something I really like doing. Just ended up being good at it. I never figured I'd be so busy during retirement. By the end of the year I'll be at over 200 made. 14 different states and the possibility of 1 going out of the country.

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 13

- Views

- 746