foggy

5 year old buck +

OK....so I used to make some precision reloading tools. Bullet seating gauges, headspace gauges, bullet comparators and some other techy stuff.

As such.....I spent ALLOT of time tweaking around with chamber and cartridge dimensions. I came to really appreciate how the 280 Remington cartridge....and guns so chambered....were not "butchered" up....by trying to be all-things-to-everybody.

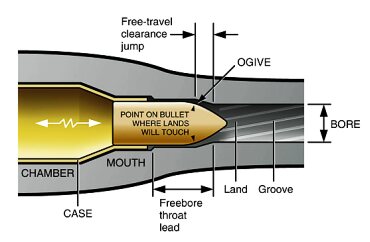

What happens to so many cartridge (SAAMI) specs is that they try to accommodate too many bullet weights to make the guns "versatile" for many purposes......and therefore may have a long throat and loose tolerances to accommodate all these larger bullets. (like bullets that range from 100gns to 220gns in the 30-06 ?? duh!) This versatility is bad for accuracy....much like a gun that is "shot-out".

Also they kept the DIAMETERS of the case neck and cartridge diameter (IIRC) from excess sizes......so the case fits better in the chamber (to promote alignment with the bore) and does not "rattle around" in the chamber. These thing REALLY promote accuracy in a factory chamber. Then too.....with a "short throat" you can seat the bullets out near the rifling to further promote accuracy! Win / win / win.

Some of this info also is true to some extent with a few other cartridges out there......but none so much as the 280 Remington.....IMHO. Consider it.....if you are really into long-range, precision shooting for medium sized game. :) It may not be the most popular.....but it is often carried by many folks that know about such "details". ;)

As such.....I spent ALLOT of time tweaking around with chamber and cartridge dimensions. I came to really appreciate how the 280 Remington cartridge....and guns so chambered....were not "butchered" up....by trying to be all-things-to-everybody.

What happens to so many cartridge (SAAMI) specs is that they try to accommodate too many bullet weights to make the guns "versatile" for many purposes......and therefore may have a long throat and loose tolerances to accommodate all these larger bullets. (like bullets that range from 100gns to 220gns in the 30-06 ?? duh!) This versatility is bad for accuracy....much like a gun that is "shot-out".

Also they kept the DIAMETERS of the case neck and cartridge diameter (IIRC) from excess sizes......so the case fits better in the chamber (to promote alignment with the bore) and does not "rattle around" in the chamber. These thing REALLY promote accuracy in a factory chamber. Then too.....with a "short throat" you can seat the bullets out near the rifling to further promote accuracy! Win / win / win.

Some of this info also is true to some extent with a few other cartridges out there......but none so much as the 280 Remington.....IMHO. Consider it.....if you are really into long-range, precision shooting for medium sized game. :) It may not be the most popular.....but it is often carried by many folks that know about such "details". ;)

View Images

View Images