Jim Timber

5 year old buck +

....and I bet you would win that welding bet. ;)

Challenge him to being old and ornery - you'll kick his punk ass! :D

So I was pretty darn close on my 120 degree guess:

I haven't checked the unbulged end of the outer shaft to see if the non-twisted part of the center section will fit it yet, but that'll happen shortly.

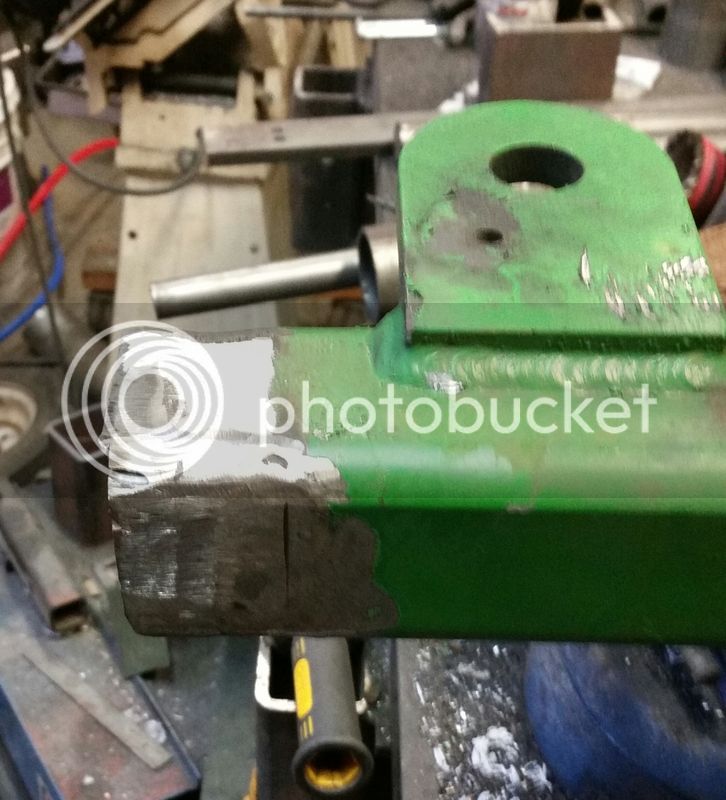

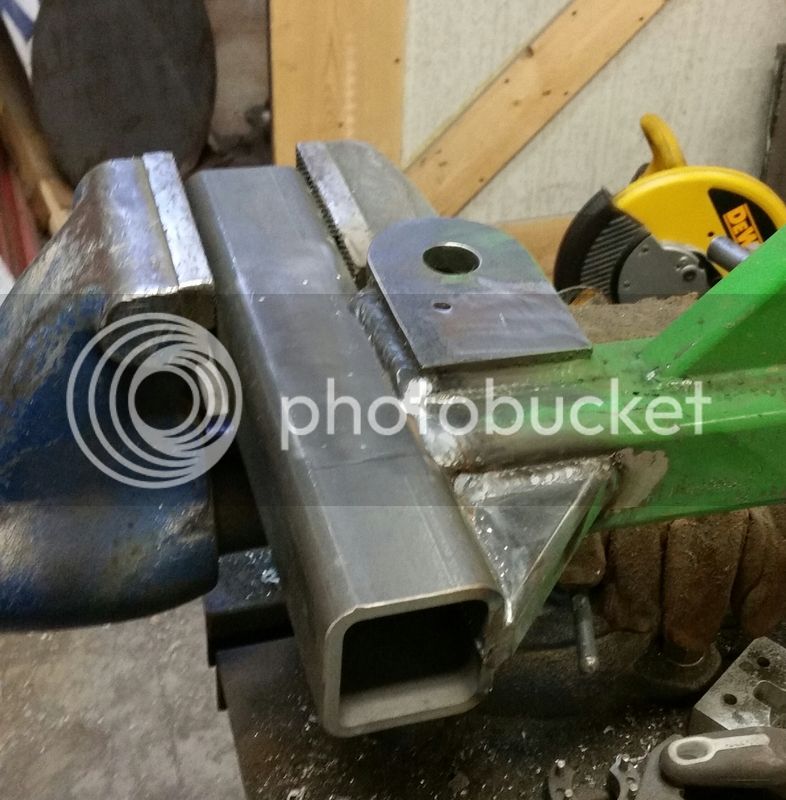

The bushing block held on for a long time before snapping. These used to be square to one another:

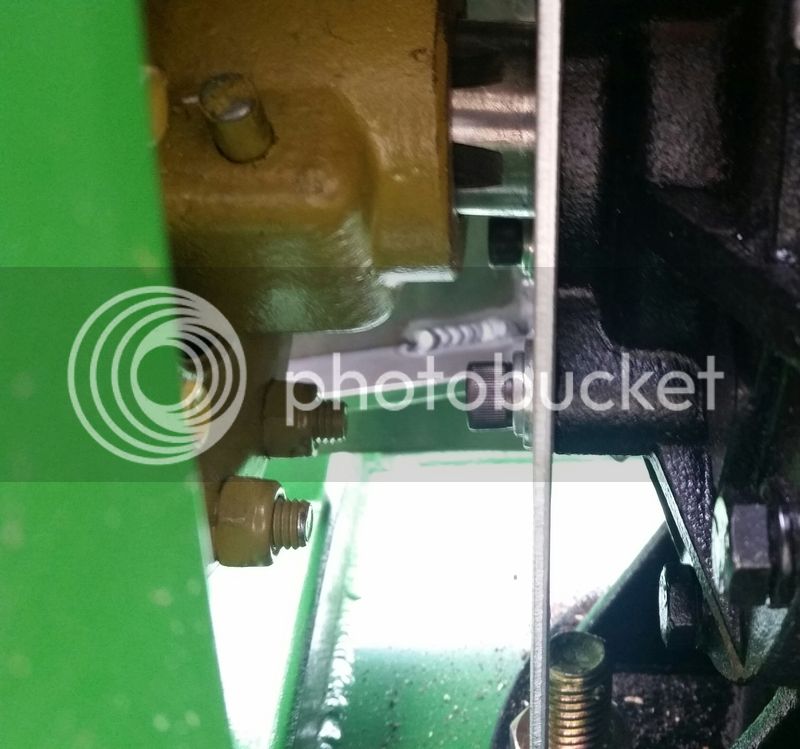

Getting these apart could be tricky:

Neither retaining pin is budging at the moment. I'm going to disassemble the clutch and that'll hopefully get me to where I can put a gear puller or similar contraption on the shaft to separate them.