Foggy47

5 year old buck +

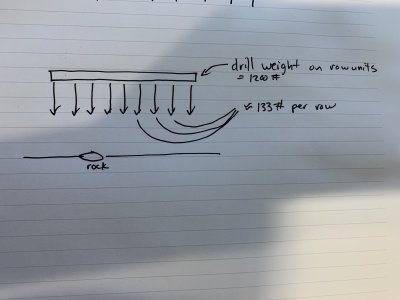

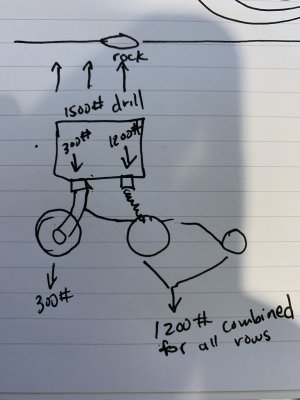

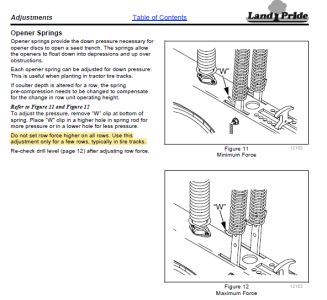

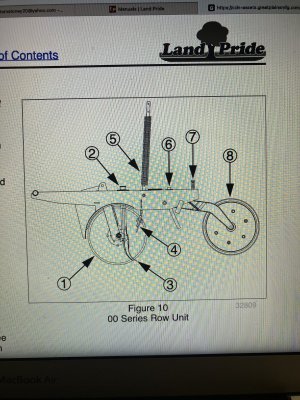

Then why not simply put more pre-load on those springs? .....by shortening their length (not) or increasing their force (yes). <----in the second case more weight will help......IMO.The spring will compress more with more weigh on them = more pre-load.

I really don't think the spring down-force will be significantly greater by shortening the spring. I believe those are more constant rate springs....and will require a change in force (stronger spring rate) to help in this area. (but I am not positive....lol). We got any engineers in this place?

___________________

Constant-force spring

From Wikipedia, the free encyclopedia

An ideal constant-force spring is a spring for which the force it exerts over its range of motion is a constant, that is, it does not obey Hooke's law. In reality, "constant-force springs" do not provide a truly constant force and are constructed from materials which do obey Hooke's law. Generally constant-force springs are constructed as a rolled ribbon of spring steel such that the spring is in a rolled up form when relaxed.

As the spring is unrolled, the material coming off the roll (un)bends from the radius of the roll into a straight line between the reel and the load. Because the material tension-stiffness of the straight section is orders of magnitude greater than the bending stiffness of the ribbon, the straight section does not stretch significantly, the restoring force comes primarily from the deformation of the portion of the ribbon near the roll. Because the geometry of that region remains nearly constant as the spring unrolls (with material coming off the roll joining the curved section, and material in the curved section joining the straight section), the resulting force is nearly constant.

_______________

I really got no horse in this race. My drill works good presently. But I do enjoy figuring it out.

Last edited: