-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GP/LP 3P600 or 3P606NT user thread

- Thread starter Brian662

- Start date

Wind Gypsy

5 year old buck +

Virgin passes with my 3p600 yesterday - I've got some learning to do yet but I'm thinking I'll need to get some more weight on it for the row units to work as well as I want them to.

The L3560 Kubota lifts it easily but there is no mistaking that it squats quite a bit when lifted vs on the ground.

The L3560 Kubota lifts it easily but there is no mistaking that it squats quite a bit when lifted vs on the ground.

Brokenbear

5 year old buck +

What hole is your drive tire in

What position is the setting of the row unit spring tension clip

What position were the “T” handles in on each of the row unit press wheel adjusters

What position is the setting of the row unit spring tension clip

What position were the “T” handles in on each of the row unit press wheel adjusters

Wind Gypsy

5 year old buck +

What hole is your drive tire in

What position is the setting of the row unit spring tension clip

What position were the “T” handles in on each of the row unit press wheel adjusters

Drive wheel is in middle (factory) setting. Spring tension clips are in standard (factory) position. T-Handles were 4th hole in from the shallow end (I.E. quite shallow).

I adjusted the tilt (top link) of the drill a bunch to play with things. Even with the shallow press wheel settings, the openers were not getting in the ground enough to have consistent down pressure on press wheels. If I stopped and went to check on things, (without lifting the drill), it was common to be able to lift half or more of the press wheels off the ground because there was no down pressure on them from the row units. This was still the case even when the top link was extended as long I could go and still get the drive wheel to turn. Even such that the drive wheel was occasionally slipping/skipping, there wasn't enough down pressure on the row units for the soil conditions IMO.

I had just rye in the main box and clover/rape in the small box. Seed was getting put in the furrow and between the seed flap and the light roller pressure, most seed was still covered, it was just less than 1/2" deep in most cases. Should make for great functional food plot planting with rye but i'm gonna want better with bigger seed like peas and beans.

Brokenbear

5 year old buck +

WG as you well know I am also new with my 3P606NT so I'm just kicking the can around with no solid written in stone "do this" scenario

Also my machine has the 606 series units and yours the 600's and I do not honestly know the physical/mechanical difference so I can only make comments based on my limited knowledge ..with that said ..

Choice one based on your comment as to un-naturally dry conditions/hard ground is to do nothing unless you need before spring to plant the larger seed

Choice two is set the Tee handles to deep and try that

Choice 3 and 4 will take some effort or it would be effort for me ..#3 move the drive wheel to top or near top hole to let it go deeper (dropping all units deeper at once)

Choice 4 would be to set the unit springs to their highest down pressure setting (factory spec range is 90 to 180lbs down pressure ..you won't easily grab a unit and lift it when set at 180lbs!)(or at least I would not)

I know you will make one change at a time by doing one change and try a short run ..then another etc.

The thing is on my machine which has all 3 hoppers ..the front tool bar is where the factory brackets go for the suitcase weights ..and it is dang unhandy having those two big azz brackets in the way ..because of the brackets ..I cannot turn my drive shaft from the outside of the machine while calibrating as the weight bracket blocks outside access ..so I use the crank on the inside stub of the shaft which is a hard angle as well as a dang close fit if hooked to the tractor

I think you have a lot of options open that you are just going to have to work'em out so hang in there buddie

Bear

Also my machine has the 606 series units and yours the 600's and I do not honestly know the physical/mechanical difference so I can only make comments based on my limited knowledge ..with that said ..

Choice one based on your comment as to un-naturally dry conditions/hard ground is to do nothing unless you need before spring to plant the larger seed

Choice two is set the Tee handles to deep and try that

Choice 3 and 4 will take some effort or it would be effort for me ..#3 move the drive wheel to top or near top hole to let it go deeper (dropping all units deeper at once)

Choice 4 would be to set the unit springs to their highest down pressure setting (factory spec range is 90 to 180lbs down pressure ..you won't easily grab a unit and lift it when set at 180lbs!)(or at least I would not)

I know you will make one change at a time by doing one change and try a short run ..then another etc.

The thing is on my machine which has all 3 hoppers ..the front tool bar is where the factory brackets go for the suitcase weights ..and it is dang unhandy having those two big azz brackets in the way ..because of the brackets ..I cannot turn my drive shaft from the outside of the machine while calibrating as the weight bracket blocks outside access ..so I use the crank on the inside stub of the shaft which is a hard angle as well as a dang close fit if hooked to the tractor

I think you have a lot of options open that you are just going to have to work'em out so hang in there buddie

Bear

omicron1792

5 year old buck +

Wind Gypsy

5 year old buck +

I assumed those were steps.

Brokenbear

5 year old buck +

The upright tower looking object between the centralized lube center and the black plastics manuals container is the factory bracket ..

There is of course a matching bracket on the other end of the tool bar ..I know the bracket will hold 2 100lb suitcase weight per bracket as it came with 4 each 100lb weights

I have never had a need for the weights ...so far that is .. my machine w/main seed box only show 2280# ..my reading and relegated to memory the adding of the small seed box adds a pinch under an additional 200# and my native seed box adds another 435# ...so I am trucking along with 2915# + 75# for the weight brackets without one grain of seed in the hopper ..I hope I never encounter conditions where I need the suitcase weights on the drill ..

Tractor is a JD5045E w/ FEL (in which I carry the 4 100# suitcase weights in the bucket when hooked up to "DeBeast"

NOTE: the 3P606NT units have the exact down pressure rating of 90# to 180# per unit as does the 3P600

So I have 9 units on my machine X 180# = 1620# of available down force if springs set to max downward pressure ..which leaves me with roughly 1380# (not counting seed #) to distribute the unused weight to the press wheels and drive tire however the coulters are factory "preloaded" to 450# each BUT ..that does not mean that much weight is being supported by the coulters as they are factory set to be just barely below the line that the unit openers sit at ..

A 3P600 has the same down pressure as the 3P606NT of 1620# and weighs 1466# big box only and 1586# with small grain box added but no coulters in place to rob weight from down pressure effort ..so full grain boxes would get you close (600/700#) would come close to maxing the penetration ability of the units on the 600

The top link is of no value at all other than to start with the machine/main seed box level with the ground and from there it is strictly drive tire setting, Press wheel T handle setting and down pressure unit spring tension

Foggy47

5 year old buck +

Those stirrups are supposed give you a step to let you "jump up" onto the wallboard. (Riiight) Those are what I positioned further to the rear and made a second walk board / step which allows an old duffer like me to climb up on the drill.

Here is what my almost finished walk board / step looks like. I had to reposition the foam marker nozzles lower. I used to need to strap a small ladder on my drill so I could look in the seed boxes. That got real old. This really works nice. Just drill a couple holes.....move those OEM "stirrps" further back.....and get a section of steel grate. Bingo!

Last edited:

Foggy47

5 year old buck +

In my case....after a few try's.....my drill was either too deep.....or my drive wheel was skipping. The guy that had my drill used it for soybeans and was planting quite deep. I moved the front tire down about 3 notches and was still unhappy. One more move and I was able to level the drill with the coulters at the right depth for me (basically 3/4") and I was further able to tweak the seed depth by positioning the press wheels / and or the top link provides some changes. My drive wheel never skips a beat.....and the drill is level - front to back.

I think it's really important to get as little influence on the drill as possible by adjusting that top link so it's basically "neutral" with the drill level and in operating mode. My drill penetrates the ground quite well in my soils. Not sure in the future if I create excessive duff or trash on the surface.....but I have been able to penetrate virgin sod without a big issue (nuked twice before drilling).

I do agree there is a learning curve to getting a new drill set up for your land. And with the "minimum till drills" you don't get much room to error.

I do wish that drive wheel was easier to change depth.....it was a real pistol for me....the chain tension device was kinda wicked to work with.

I think it's really important to get as little influence on the drill as possible by adjusting that top link so it's basically "neutral" with the drill level and in operating mode. My drill penetrates the ground quite well in my soils. Not sure in the future if I create excessive duff or trash on the surface.....but I have been able to penetrate virgin sod without a big issue (nuked twice before drilling).

I do agree there is a learning curve to getting a new drill set up for your land. And with the "minimum till drills" you don't get much room to error.

I do wish that drive wheel was easier to change depth.....it was a real pistol for me....the chain tension device was kinda wicked to work with.

Wind Gypsy

5 year old buck +

View attachment 58223

The upright tower looking object between the centralized lube center and the black plastics manuals container is the factory bracket ..

There is of course a matching bracket on the other end of the tool bar ..I know the bracket will hold 2 100lb suitcase weight per bracket as it came with 4 each 100lb weights

I have never had a need for the weights ...so far that is .. my machine w/main seed box only show 2280# ..my reading and relegated to memory the adding of the small seed box adds a pinch under an additional 200# and my native seed box adds another 435# ...so I am trucking along with 2915# + 75# for the weight brackets without one grain of seed in the hopper ..I hope I never encounter conditions where I need the suitcase weights on the drill ..

Tractor is a JD5045E w/ FEL (in which I carry the 4 100# suitcase weights in the bucket when hooked up to "DeBeast"

NOTE: the 3P606NT units have the exact down pressure rating of 90# to 180# per unit as does the 3P600

So I have 9 units on my machine X 180# = 1620# of available down force if springs set to max downward pressure ..which leaves me with roughly 1380# (not counting seed #) to distribute the unused weight to the press wheels and drive tire however the coulters are factory "preloaded" to 450# each BUT ..that does not mean that much weight is being supported by the coulters as they are factory set to be just barely below the line that the unit openers sit at ..

A 3P600 has the same down pressure as the 3P606NT of 1620# and weighs 1466# big box only and 1586# with small grain box added but no coulters in place to rob weight from down pressure effort ..so full grain boxes would get you close (600/700#) would come close to maxing the penetration ability of the units on the 600

Your drill with the same # of rows as a 3p600 weighs twice as much. It may not be apples to apples since there is the addition of coulters but its for sure going to get row units in the ground easier with twice the weight. My understanding is the spring preload just changes how easily each row unit moves with changing ground elevations and resistance to penetration. If the drill weighs 1500# and say 300# of that is supported by the drive wheel, there's 1200# of down pressure distributed between 9 row units, that's the same regardless of the spring pre-load. The only way to get more down pressure is to add weight. All having a higher preload does is make that row or coulter less likely to compress up when it hits resistance from residue or a high spot - the negative to that is when the higher preload spring in a coulter or opener hits resistance it reduces the down pressure available to all of the other coulters/openers.

The top link is of no value at all other than to start with the machine/main seed box level with the ground and from there it is strictly drive tire setting, Press wheel T handle setting and down pressure unit spring tension

I think the top link can have a significant impact on how the drill operates because it restricts a drills freedom to follow the up and down contours or at least takes or imparts some loads to how the downforces balance fore and aft in the drill. I'm going to float my top link eventually and think that will be an improvement on this drill.

you think the T handles are the first thing we should adjust for depth control? After assuring planter is level, or should we look elsewhere?

I have same problem in my hard clay Ky ground

If your closing wheels aren't putting a fair bit a down pressure on the ground because the openers aren't penetrating, they aren't making much difference in depth IMO. I'm guessing getting more weight on your row units is the main thing that will make a difference.

Brokenbear

5 year old buck +

I reiterate I am a short time owner of my 3P606NT but I studied long and hard to make sure that the Great Plains has the most independent of tractor movement 3 point drill on the market (not relying on the 3 pt lift arms for any part of the drill depth control ) (properly set the undulations of the tractor should not transfer to the drill ..there are limits of course)

In that vein the manuals as well as soil conservation district seminars attended/lead by Great Plains sales and engineering staff repeated several times that depth was solely managed by drive tire setting, unit Tee handle setting and spring down pressure setting as well .. all starts with leveling the drill and then leaving the top link alone

To address your exact questions ..the quickest move is the Tee handles if looking for just a touch deeper ..BUT in truth IF you do not proportionately raise the hole setting on the drive wheel you could maybe get 1/4" or even 1/2" more depth but you will give up press wheel pressure when you do

The drive wheel hole change once you have done it once is a 20 minuet deal ..it looks complicated but really it is simply loosen BOTH chain idlers ..pull the drive wheel axle bolt and set to it's new position and move the two chain idlers back in place to re-tension the chain ..we are not talking even removing,shortening or lengthening or adding or taking out chain links from the the chain ..it stays in place thru the entire process

The unit spring tension adjustment for me will be the hardest with rebuilt shoulders and I have not needed to do so and therefore have not studied them yet to determine the most economical process to effect the change ..yet .. but I'm pretty sure it will best be affected with the drill free from the tractor

In that vein the manuals as well as soil conservation district seminars attended/lead by Great Plains sales and engineering staff repeated several times that depth was solely managed by drive tire setting, unit Tee handle setting and spring down pressure setting as well .. all starts with leveling the drill and then leaving the top link alone

To address your exact questions ..the quickest move is the Tee handles if looking for just a touch deeper ..BUT in truth IF you do not proportionately raise the hole setting on the drive wheel you could maybe get 1/4" or even 1/2" more depth but you will give up press wheel pressure when you do

The drive wheel hole change once you have done it once is a 20 minuet deal ..it looks complicated but really it is simply loosen BOTH chain idlers ..pull the drive wheel axle bolt and set to it's new position and move the two chain idlers back in place to re-tension the chain ..we are not talking even removing,shortening or lengthening or adding or taking out chain links from the the chain ..it stays in place thru the entire process

The unit spring tension adjustment for me will be the hardest with rebuilt shoulders and I have not needed to do so and therefore have not studied them yet to determine the most economical process to effect the change ..yet .. but I'm pretty sure it will best be affected with the drill free from the tractor

Brokenbear

5 year old buck +

What if's :

does this make sense ..if on the 3P600 you raised the drive tire to a hole to where the drive tire is just even with or with in 1/2" =/- of the openers and set the Tee's to deep on the scale just to see if the machine has the weight to penetrate the dry ground ...

I had to soak over night with penetrate oil my drive tire chain tensioners .. cleaning up the bolt threads and slide areas then greased them and now they are easy peasy ..I do not think the prior owner ever moved the drive wheel !

does this make sense ..if on the 3P600 you raised the drive tire to a hole to where the drive tire is just even with or with in 1/2" =/- of the openers and set the Tee's to deep on the scale just to see if the machine has the weight to penetrate the dry ground ...

I had to soak over night with penetrate oil my drive tire chain tensioners .. cleaning up the bolt threads and slide areas then greased them and now they are easy peasy ..I do not think the prior owner ever moved the drive wheel !

Wind Gypsy

5 year old buck +

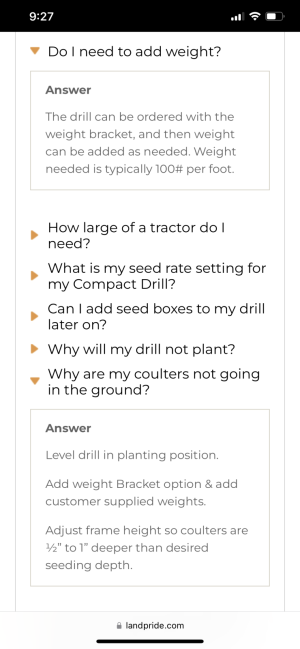

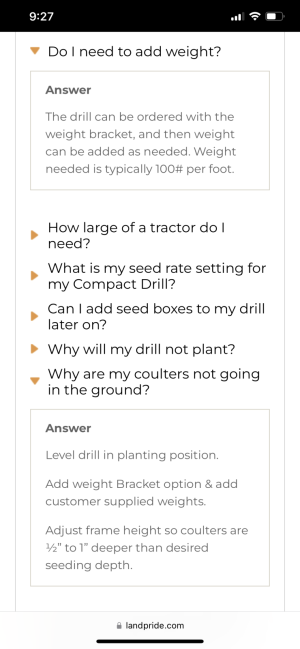

I could see moving the drive wheel up possibly shifting a little more weight to the row units but i think the long and short of it is the drill just needs more weight on the openers. The tech i spoke with today agreed. The below screenshot is from the landpride 3p600 product page but i believe it is just a copy of what they have from no-till versions. The tech support folks have been unable to find any such weight brackets for the min till drills.

Foggy47

5 year old buck +

When I get back to MN.....I intend to look for a location to add some suitcase weights to the sides of the drill. I beleive I could hang a bracket on both sides of the drill......and they weights could be attached parallel to that big plate that is basically the whole side of the drill. Thus the suitcase weights would only protrude a few inches. Perhaps bolting something like 3/8" x 3" x 6" rectangular tubes ......say about 10" long.....would provide a mount for two suitcase weights? - one facing front and another facing rearward.

LOL....I don't really think I need more weight....but it's fun to figure out solutions.

LOL....I don't really think I need more weight....but it's fun to figure out solutions.

Wind Gypsy

5 year old buck +

When I get back to MN.....I intend to look for a location to add some suitcase weights to the sides of the drill. I beleive I could hang a bracket on both sides of the drill......and they weights could be attached parallel to that big plate that is basically the whole side of the drill. Thus the suitcase weights would only protrude a few inches. Perhaps bolting something like 3/8" x 3" x 6" rectangular tubes ......say about 10" long.....would provide a mount for two suitcase weights? - one facing front and another facing rearward.

LOL....I don't really think I need more weight....but it's fun to figure out solutions.

I’m all for having foggy on board creating solutions. If nothing else I might just build a border around the back platform with 2x6s and lay some suitcase weights flat on top of the platform.

Foggy47

5 year old buck +

^ Plausible. The thing is....that walkboard is pretty useful for adding seed and cleanup. Kinda hate to clobber that spot up with weight.I’m all for having foggy on board creating solutions. If nothing else I might just build a border around the back platform with 2x6s and lay some suitcase weights flat on top of the platform.

I was just looking at a pic of the sides of those drills. It appears that bolting a fabricated bracket to either side of those main frame side slabs (not the hopper) could work pretty well. I think you could hang 2 suitcase weights per side. The suitcase weights I have are 70 lbs a piece. Thus including the brackets you could easily add 300 lbs.

There also may be enough area to add one weight on each side in the inside front of the main frame. Thus another 150 lbs added weight (450# total). I bleieve all All could be bolt on....and would not impair the function of the drill.

I do wonder tho.....if the individual row units would actually penetrate better for you?.....or are they more a function of that spring pre-load. Dunno. Makes me wonder about finding heavier duty springs. Perhaps from another drill model?

Wind Gypsy

5 year old buck +

I do wonder tho.....if the individual row units would actually penetrate better for you?.....or are they more a function of that spring pre-load. Dunno. Makes me wonder about finding heavier duty springs. Perhaps from another drill model?

The spring will compress more with more weigh on them = more pre-load.