-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GP/LP 3P600 or 3P606NT user thread

- Thread starter Brian662

- Start date

Foggy47

5 year old buck +

I have a hydraulic top link and will tweak it back and forth to find where the top link is more or less nueteral and not got any pressure on it when in the ground. My land is pretty flat so I have not seen issues when operated this way. I have not floated the top link but I do have a float position in my valve. I suppose I could try floating the top link.

I've read that some folks have had their tire foam filled. It would be fairly easy to remove it and take it to a good tire shop for this.......but I do not plan to do that.....unless I have lots of problems.

I put mine on a platform truck so I. can move mine around on wheels. The coulters and wheels all sit on the wooden deck.

I've read that some folks have had their tire foam filled. It would be fairly easy to remove it and take it to a good tire shop for this.......but I do not plan to do that.....unless I have lots of problems.

I put mine on a platform truck so I. can move mine around on wheels. The coulters and wheels all sit on the wooden deck.

Foggy47

5 year old buck +

One thing that I find needs to be addressed .....is that the size of that top link hole is set up for category 2. the lower pins are category one or two.....but not so on that top link. I did not like having that extra 1/4" of difference between my catagory 1 pin and the category two hole. I bought some shoulder bushings and came up with a method to retain those shoulder bushings perfectly via some washers and a standard top link pin.

Bought the bushings at Mac Carr for about $10. / pair. Will take a pic and post part numbers later. I feel this needs to be done or over time it could batter up that top hole.

Not sure what others have done....but it is difficult to shim down in size. Seems odd GP did this.

Bought the bushings at Mac Carr for about $10. / pair. Will take a pic and post part numbers later. I feel this needs to be done or over time it could batter up that top hole.

Not sure what others have done....but it is difficult to shim down in size. Seems odd GP did this.

omicron1792

5 year old buck +

I use this Wind.

Hildirix Versatile Quick Hitch Adapter Used to Adjust Top Link Bracket Movements Fit for Category 1 Quick Hitch https://a.co/d/b3W8STJ

Also my land has lots of elevation change. I, like Foggy, adjust the level with hydraulic a good bit. If totally flat fields maybe you don’t need it. For me, I use it a bunch. I find I can have it level, and will look back and tire not engaging so not planting. So I adjust if toward and keep going without getting off tractor.

Hildirix Versatile Quick Hitch Adapter Used to Adjust Top Link Bracket Movements Fit for Category 1 Quick Hitch https://a.co/d/b3W8STJ

Also my land has lots of elevation change. I, like Foggy, adjust the level with hydraulic a good bit. If totally flat fields maybe you don’t need it. For me, I use it a bunch. I find I can have it level, and will look back and tire not engaging so not planting. So I adjust if toward and keep going without getting off tractor.

omicron1792

5 year old buck +

I have cat 1 quick hitch, so I put a cat 1 to cat 2 bushing on the bottom pins. They have a pin that secures them so just a one time fix.One thing that I find needs to be addressed .....is that the size of that top link hole is set up for category 2. the lower pins are category one or two.....but not so on that top link. I did not like having that extra 1/4" of difference between my catagory 1 pin and the category two hole. I bought some shoulder bushings and came up with a method to retain those shoulder bushings perfectly via some washers and a standard top link pin.

Bought the bushings at Mac Carr for about $10. / pair. Will take a pic and post part numbers later. I feel this needs to be done or over time it could batter up that top hole.

Not sure what others have done....but it is difficult to shim down in size. Seems odd GP did this.

Foggy47

5 year old buck +

OK....I'm not a Quick Hitch fan. I use PAT'S EZ lower links and a Hydraulic Top link. Works for me and my toys.I have cat 1 quick hitch, so I put a cat 1 to cat 2 bushing on the bottom pins. They have a pin that secures them so just a one time fix.

Foggy47

5 year old buck +

Here are the top link bushings I bought at MacMaster Carr. Worked perfectly for me. With a category 1 Pin and my Hydraulic top link. I will see if I got a pic of the machine hook up.

1

Oil-Embedded Flanged Sleeve Bearing For 3/4" Shaft, 1" Housing Id, 3/4" Long, 1-1/8"Flange Od

6338K581

2

Each

$4.96

Each

Edit: Attached is a pic of my hydraulic top link. Those bushings are located on the machine end.....and I use large washers to prevent the pin from working from one side to the other.....where it could get into the drive chain. It's a sound set up. You cannot see the bushings as those washers are covering them. I put the flanged walls on the inside of the attachment and my top link fits perfectly between the shoulders....thus the bushings will not migrate side to side and are contained by the top link.

1

Oil-Embedded Flanged Sleeve Bearing For 3/4" Shaft, 1" Housing Id, 3/4" Long, 1-1/8"Flange Od

6338K581

2

Each

$4.96

Each

Edit: Attached is a pic of my hydraulic top link. Those bushings are located on the machine end.....and I use large washers to prevent the pin from working from one side to the other.....where it could get into the drive chain. It's a sound set up. You cannot see the bushings as those washers are covering them. I put the flanged walls on the inside of the attachment and my top link fits perfectly between the shoulders....thus the bushings will not migrate side to side and are contained by the top link.

Last edited:

Wind Gypsy

5 year old buck +

I use this Wind.

Hildirix Versatile Quick Hitch Adapter Used to Adjust Top Link Bracket Movements Fit for Category 1 Quick Hitch https://a.co/d/b3W8STJ

Also my land has lots of elevation change. I, like Foggy, adjust the level with hydraulic a good bit. If totally flat fields maybe you don’t need it. For me, I use it a bunch. I find I can have it level, and will look back and tire not engaging so not planting. So I adjust if toward and keep going without getting off tractor.

My fields are near totally flat, they just aren't smooth. They are converted hay fields that have depressions in the direction of tractor travel from 30+ years of the ground being hayed without any tillage. Drilling in the same direction of these works well as the springs from each row seem to do their job adjusting for minor elevation changes. It's when I go perpendicular that it feels like constant small speed bumps. With a pull type drill there haven't been any issues caused by rear tractor tires rolling over these shallow bumps. I worry that with a 3point drill will be significantly more sensitive to crossing these bumps and this is why i felt floating the top link might allow the drill to roll with things a bit better. I hate to break ground that hasn't been broken in 30+ years but might do it to improve smoothness and also incorporate lime/fert. Stuff is growing well though even with low pH and P & K readings.

Last edited:

omicron1792

5 year old buck +

Your drill will do great with it.My fields are near totally flat, they just aren't smooth. My plots are converted hay fields that have depressions in the direction of tractor travel from 30+ years of the ground being hayed without any tillage. Drilling in the same direction of these works well as the springs from each row seem to do their job adjusting for minor elevation changes. It's when I go perpendicular that it feels like constant small speed bumps. With a pull type drill there haven't been any issues caused by rear tractor tires rolling over these shallow bumps. I worry that with a 3point drill will be significantly more sensitive to crossing these bumps and this is why i felt floating the top link might allow the drill to roll with things a bit better. I hate to break ground that hasn't been broken in 30+ years but might do it to improve smoothness and also incorporate lime/fert. Stuff is growing well though even with low pH and P & K readings..

I do agree though that smoothing it one time might be a benefit. When I have a dozer on property I have them smooth a field or two. Just makes it easier long term.

Foggy47

5 year old buck +

After I was satisfied with my drill depth and front wheel contact.....I pretty much left everything alone and planted my entire acreage without again adjusting the front wheel contact. I did put a bit of paint and electrical tape on a few shafts that rotate....so it becomes more evident to me if they should stop rotating. (I did have that issue early on, but not anymore).Your drill will do great with it.

I do agree though that smoothing it one time might be a benefit. When I have a dozer on property I have them smooth a field or two. Just makes it easier long term.

I think the key for me now is to adjust that top link until I see the slack go from tight to free.....and back again while on level ground. Only takes a little movement to see it. Then you'r golden on level ground.

I kinda wish I had done as suggested.....and put the top link in float mode for a time to see how that works. Never gave it a thought. Next time......if I can remember that long.

swat1018

5 year old buck +

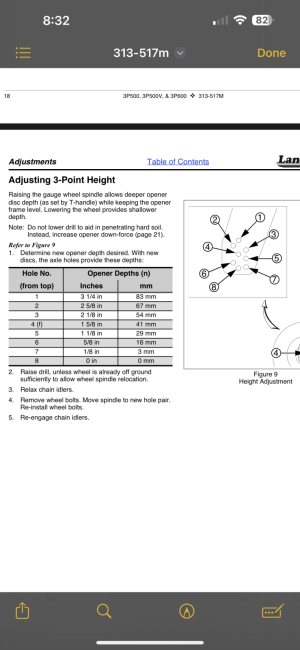

Level the drill at the lid. Don't tinker with the top link to try and keep the drive wheel on the ground. If the drive wheel skips with the drill level, most do from the factory, lower the drive wheel. I had to drop mine 2 holes. Several buddies did the same thing, Mine doesn't skip during normal use now.

omicron1792

5 year old buck +

Only thing is that can affect planting depth.Level the drill at the lid. Don't tinker with the top link to try and keep the drive wheel on the ground. If the drive wheel skips with the drill level, most do from the factory, lower the drive wheel. I had to drop mine 2 holes. Several buddies did the same thing, Mine doesn't skip during normal use now.

Now, to me the middle hole for wheel plants too deep. Almost 2 inches. So I moved drive wheel down to get my planting depth just under an inch.

Wind Gypsy

5 year old buck +

Say there’s a 12” wide high spot - if the top link is not floating then when the drive wheel rolls over it wouldn’t that transfer significant down pressure from the openers and closing wheels to the drive wheel and thus plant shallower and or not close up the furrow as well as a drill that’s able to pivot a little with the ground?

Foggy47

5 year old buck +

Drills are an odd machine to wrap your head around...and even more difficult to write about the operation. Great Plains / Land Pride has a good set up as the rows are independent to a great extent.Say there’s a 12” wide high spot - if the top link is not floating then when the drive wheel rolls over it wouldn’t that transfer significant down pressure from the openers and closing wheels to the drive wheel and thus plant shallower and or not close up the furrow as well as a drill that’s able to pivot a little with the ground?

Consider this thought. The drill openers and row units are semi independent and loaded by down force spring on the row units. To a great extent....the entire weight of the machine rests on that front drive tire and the rear closing wheels to the limit of closing wheel settings. Thus the springs providing down force (somewhere at about 140 # row) and the independent double disk openers slice into the soil at their pre-adjusted spring force which keeps them operating mostly along the ground contours.....and at the same depth level setting. All of which is maxed out by the closing wheel settings. The front drive wheel has no suspension. if the drill is set up correctly much of the load is carried by those disk openers....but that front wheel needs to stay engaged with the soil in order to operate the seed opener mechanism. (Phew!)

Thus in operation, when the tractors lower links are all the way down the links are merely pulling the drill. They are not carrying the drill. When you encounter a rock or a stump those individual row units will travel up and over that stump to the amount of free travel in each row unit.....if the machine uses up all the allowed free travel then the whole drill will ride up and over the obstacle. <----this could put allot of force on those row units encountering the obstacle.....and it's how damage can happen. Be careful. Go slow. grin.

Having a floating top link would add another factor. Not sure which is "better" but the drill was not designed around the need for a floating top link or a hydraulic top link. A hydraulic top link does make set up easier to level and to keep the drive wheel engaged.

Last edited:

Foggy47

5 year old buck +

It got "old" hanging around home and the computer all day. I'm getting over a cold I picked up the other day. (no covid!)

I had to get out of the house.....so I made a trip to Deertopia which is about 15 minutes from home. Wanted to fix an issue with my drill. When I was drilling seeds. I noticed that a few row units had missing "seed flaps". I was unsure how those work.....so I lifted the drill a bit and removed one of the disk blades. Below is a picture of the seed drop for the main seed box. The main seed box drops the seeds though the tube on the left and the rubber flap contains those seeds from bouncing out of the V-trench cut by the openers. The small seed box drops seeds behind that rubber flap.

I saw I had a few of those flaps missing......so I wanted to determine how to replace them and order some parts. Turns out you can replace them without removing the blades......it just takes a needle now pliers to put the rubber flap into place. They sell these in bundles of 25 for like $50. Geesh. So I went to the Messner site and ordered 3 of them for $4.50 a piece. I suppose I could have cut some from some rubber roofing stock I have.....alas.....I paid the price.

Also bought a few of those covers for the main seed box.....which will simplify my calibration......and in case I want to plant some corn or beans, etc. I wanted my drill to be up to speed when I use it next year. Good to know how this works. I sure like their seed deliver set up.

EDIT: OH....and notice the small box tube at the extreme right of the pic above. Those seeds are place on top of the front box seeds and may bounce around a bit....a good thing as they are still pressed by the press-wheels.

I had to get out of the house.....so I made a trip to Deertopia which is about 15 minutes from home. Wanted to fix an issue with my drill. When I was drilling seeds. I noticed that a few row units had missing "seed flaps". I was unsure how those work.....so I lifted the drill a bit and removed one of the disk blades. Below is a picture of the seed drop for the main seed box. The main seed box drops the seeds though the tube on the left and the rubber flap contains those seeds from bouncing out of the V-trench cut by the openers. The small seed box drops seeds behind that rubber flap.

I saw I had a few of those flaps missing......so I wanted to determine how to replace them and order some parts. Turns out you can replace them without removing the blades......it just takes a needle now pliers to put the rubber flap into place. They sell these in bundles of 25 for like $50. Geesh. So I went to the Messner site and ordered 3 of them for $4.50 a piece. I suppose I could have cut some from some rubber roofing stock I have.....alas.....I paid the price.

Also bought a few of those covers for the main seed box.....which will simplify my calibration......and in case I want to plant some corn or beans, etc. I wanted my drill to be up to speed when I use it next year. Good to know how this works. I sure like their seed deliver set up.

EDIT: OH....and notice the small box tube at the extreme right of the pic above. Those seeds are place on top of the front box seeds and may bounce around a bit....a good thing as they are still pressed by the press-wheels.

swat1018

5 year old buck +

Only thing is that can affect planting depth.

Now, to me the middle hole for wheel plants too deep. Almost 2 inches. So I moved drive wheel down to get my planting depth just under an inch.

I don't buy it. If the wheel is skipping where it was (insufficient pressure), lowering it to where it stays in contact with the ground will be negligible. Planting depth is controlled by the "T" handles mainly.

Foggy47

5 year old buck +

I think Omi said his was planting too deep so he set that front wheel lower. I had to do this too. Mine was set up for 1.5" to 2.5" or so (beans).I don't buy it. If the wheel is skipping where it was (insufficient pressure), lowering it to where it stays in contact with the ground will be negligible. Planting depth is controlled by the "T" handles mainly.

omicron1792

5 year old buck +

You don’t have to buy it. It’s been told to you for free.I don't buy it. If the wheel is skipping where it was (insufficient pressure), lowering it to where it stays in contact with the ground will be negligible. Planting depth is controlled by the "T" handles mainly.

T handle for press wheels give you how far in the trench the seed is pressed. Has 0.000 to do with how deep the trench is. That’s set by slot where the wheel is.

Wind Gypsy

5 year old buck +

It got "old" hanging around home and the computer all day. I'm getting over a cold I picked up the other day. (no covid!)

I had to get out of the house.....so I made a trip to Deertopia which is about 15 minutes from home. Wanted to fix an issue with my drill. When I was drilling seeds. I noticed that a few row units had missing "seed flaps". I was unsure how those work.....so I lifted the drill a bit and removed one of the disk blades. Below is a picture of the seed drop for the main seed box. The main seed box drops the seeds though the tube on the left and the rubber flap contains those seeds from bouncing out of the V-trench cut by the openers. The small seed box drops seeds behind that rubber flap.

View attachment 56929

I saw I had a few of those flaps missing......so I wanted to determine how to replace them and order some parts. Turns out you can replace them without removing the blades......it just takes a needle now pliers to put the rubber flap into place. They sell these in bundles of 25 for like $50. Geesh. So I went to the Messner site and ordered 3 of them for $4.50 a piece. I suppose I could have cut some from some rubber roofing stock I have.....alas.....I paid the price.

Also bought a few of those covers for the main seed box.....which will simplify my calibration......and in case I want to plant some corn or beans, etc. I wanted my drill to be up to speed when I use it next year. Good to know how this works. I sure like their seed deliver set up.

EDIT: OH....and notice the small box tube at the extreme right of the pic above. Those seeds are place on top of the front box seeds and may bounce around a bit....a good thing as they are still pressed by the press-wheels.

Foggy, have you read he part in the manual about the direction of the small seed tubes? Basically the way yours are pointing (towards the openers) is more likely to drop seeds deeper in the trench than if they are rotated 180 degrees and pointing more towards the closing wheels.

Foggy47

5 year old buck +

Yep and I considered that. When you position to the rear....the seeds will be scattered on the ground largely after the walls of the trench may have collapsed to some degree....rather than on top of the seeds coming out of the front box (and somewhat to both sides) of the trench. The small seeds do tend to scatter a bit. Some feel the front to be better and some the back. I'm not sure....but in my sand, I feel better off getting some seed covered. Especially if the seeds may have to sit for a while without moisture.Foggy, have you read he part in the manual about the direction of the small seed tubes? Basically the way yours are pointing (towards the openers) is more likely to drop seeds deeper in the trench than if they are rotated 180 degrees and pointing more towards the closing wheels.

Some say that the deeper seeds from the front box (in my case some cereal rye, AWP's, GH Radish) will push the smaller seeds up as the bigger ones emerge. Wonder about surveying what others do???

I wonder which direction the new drills are furnished? Anyone??

Last edited: