Doug Galloway

5 year old buck +

Thanks for the idea and tip for this in the cultipacker thread. I will add another helpful trick....dip the tip of a deck screw or lag screw into 20W-50 motor oil before driving them...works slick! pun lol

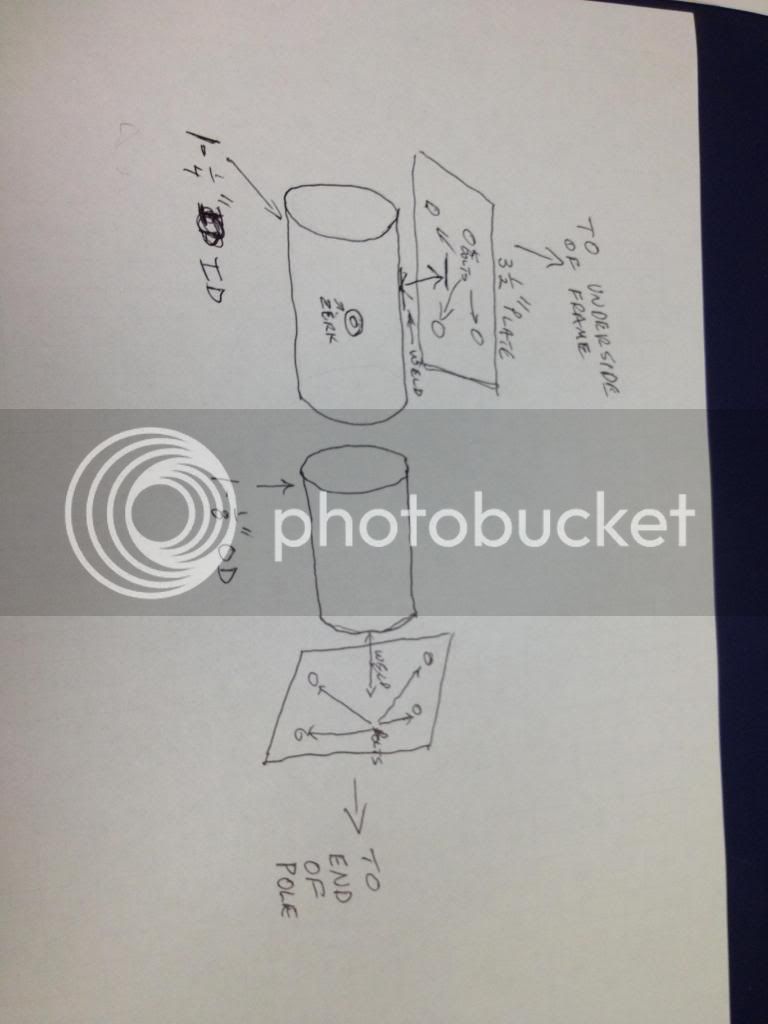

This is a heavy wooden frame for a 10'6" cover crop roller....made from new treated lumber and the auto tow hitch from Harbor Freight. Included some close ups of corner bracing and a mod on the hitch attachment.

An 18-24" diameter log from an old creosoted transmission line pole will be used for the roller. Risers angling toward the back of the unit will hold a 10' boom sprayer.

In one pass, a cover crop can be rolled and sprayed....goal is to save time on planting day and reduce the need for helpers!

If it doesn't work....we aren't out much!

Vanna White showed up for a photo op!...and yes my lawn is overseeded in a cover crop!

This is a heavy wooden frame for a 10'6" cover crop roller....made from new treated lumber and the auto tow hitch from Harbor Freight. Included some close ups of corner bracing and a mod on the hitch attachment.

An 18-24" diameter log from an old creosoted transmission line pole will be used for the roller. Risers angling toward the back of the unit will hold a 10' boom sprayer.

In one pass, a cover crop can be rolled and sprayed....goal is to save time on planting day and reduce the need for helpers!

If it doesn't work....we aren't out much!

Vanna White showed up for a photo op!...and yes my lawn is overseeded in a cover crop!