Tree Spud

5 year old buck +

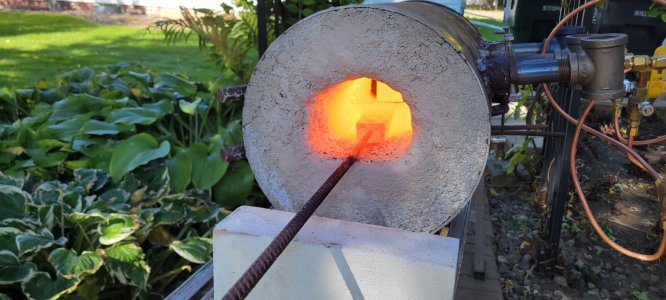

Since I've been making knives I've always wanted to build a larger forge. Currently what I'm using is only big enough to heat treat blanks. I want to be able to make some canister or stacked damascus blade blanks. I've been collecting pieces here and there and finally have time to start the build. The main body of the forge is an old air compressor tank, I've made some hinges & legs from scraps I had laying around. I have most of the parts to make the burners which there will be 3. I still need to source my supplies to line the forge with. Here's what I have so far.

View attachment 44117

I'll be following this one, lot's of details and picture of the process. please.

Damascus rocks!