-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool'n Knife Builds

- Thread starter tooln

- Start date

tooln

5 year old buck +

tooln

5 year old buck +

Got a guy in Turkey who makes them. Took about 3 weeks to get them shipped to me. They are not cheap.I like those pins! Where did you get them?

tooln

5 year old buck +

I spent the past few days at a gun/knife show. Ran into some old friends and made a few new.

Making a couple of sales also helped. Here's a short video of my latest knife that's still a work in progress. The handle scales are Curley Maple. Looking at it straight on you don't see much, but get the angle and light just right it pops.

Making a couple of sales also helped. Here's a short video of my latest knife that's still a work in progress. The handle scales are Curley Maple. Looking at it straight on you don't see much, but get the angle and light just right it pops.

Catscratch

5 year old buck +

Another one hit out of the park!

tooln

5 year old buck +

Thanks for the kind words. When I started with the curley maple I was questionable about it . In the raw state it doesn't look like much, but get it sanded and polished it pops. This will be for sale at the show in 2 weeks unless it goes before hand. I just can't keep them all.Another one hit out of the park!

tooln

5 year old buck +

Ever use stainless?

These are drop blood knifes. Stick a tuna right behind the pectoral fins and they bleed out nice for sushi grade meat.

To better answer your question about Stainless. Stainless is a another beast when it comes to heat treat and tempering. High Carbon steels like 1095 which I use are relatively easy. The process I use is they are brought up to austenite state (non magnetic) and then air cooled. Then its do it again 3 times. Then it brought up to temp again and held there for just a few minutes and it goes into a oil quench with preheated oil. It stay in the oil for 20 seconds or so. The steel is now in martensite state which is VERY brittle. To remove the brittleness It goes into a tempering oven for 2, 1 hour cycles. Temp range between 400 - 450 depending on the hardness you want. Temps are fairly critical.

Stainless is totally different. Heat treat the temps are a lot higher and the blade needs to be held at that temp for long periods of time. Depending on the stainless used temps range in the 2000+ range and the hold times can be up to an hour. Some you even need to hold at lower temps for 45 minutes to an hour, cool it and do it again with a higher temp. Some take several cycles of this. The temp are VERY critical for heat treating. To get these temps and hold for that period of time one would need a heat treat oven/kiln. These start at the 2K range and that's more than this retired guy can afford. I'd love to have one but then I'd have to be selling knives in the 400-500 dollar range. I believe I am better off sticking with what I'm doing with high carbon. Also high carbon is a lot tougher than Stainless but yes they do require a little more care. I did run across a stainless from Sweden that I believe I can heat treat and temper with the Eq. I currently have. But I've been busy getting inventory ready for local shows and orders. Once caught up I'm going to give the stainless a try. This is the short answer believe me I don't know it all and there are so many different methods and opinions on how it's done, but all agree stainless isn't easy.

Foggy47

5 year old buck +

Mike......FWIW there are some small kiln's available on FB Marketplace. See a few as low as $250. Not sure of the quality or size requirements. I been finding lots of interesting stuff on marketplace.

Maybe its time to add a trademark emblem behind Tool'n ? Lets see if I still know how to type this: Tool'n (TM). <----- Edit.....nope.

Maybe its time to add a trademark emblem behind Tool'n ? Lets see if I still know how to type this: Tool'n (TM). <----- Edit.....nope.

tooln

5 year old buck +

I've checked MP several times and really haven't seen anything. If you see something let me know. I'd need something that is good to 2200 degrees and had heating elements front to back to get a even heat soak.Mike......FWIW there are some small kiln's available on FB Marketplace. See a few as low as $250. Not sure of the quality or size requirements. I been finding lots of interesting stuff on marketplace.

Maybe its time to add a trademark emblem behind Tool'n ? Lets see if I still know how to type this: Tool'n (TM). <----- Edit.....nope.

Catscratch

5 year old buck +

Just an idea... but when I was working as a machinist we sent most of our heat treat out. There are plenty of companies that do it, probably cheaper than buying the equipment yourself. But, as a diy guy I like to have hands on every step so I get it if you don't want to do that.

tooln

5 year old buck +

I've thought about sending stuff out, both etching and heat treating. It tried a laser etch but wasn't happy with the test piece I sent. If I were doing production runs yes it would pay. But one offs like I do it wouldn't pay. I'm also a do it yourself guy. So every bit of the knife is in my control and I'm not at the mercy of others.Just an idea... but when I was working as a machinist we sent most of our heat treat out. There are plenty of companies that do it, probably cheaper than buying the equipment yourself. But, as a diy guy I like to have hands on every step so I get it if you don't want to do that.

Bill Loser

5 year old buck +

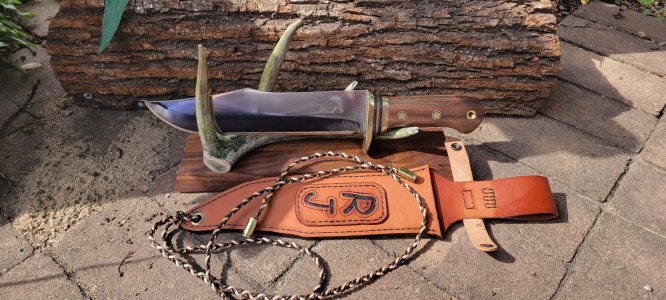

That is beautiful! Nice workFinished up another one today. 1095 blade with a gut hook. Black and Blue G10 handle scales with brass pins. Braided leather lanyard with antler tip. The sheath has a Bull Snake inlay from an confidential source.

View attachment 49638 View attachment 49639

Similar threads

- Replies

- 44

- Views

- 3K

- Replies

- 13

- Views

- 807