-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This week's tractor upgrades

- Thread starter Jim Timber

- Start date

Jim Timber

5 year old buck +

Tractor's already running 12+ psi boost. ;)

https://tractortestlab.unl.edu/c/do...3-4906-b6d1-19932c64eb52&groupId=4805395&.pdf

https://tractortestlab.unl.edu/c/do...3-4906-b6d1-19932c64eb52&groupId=4805395&.pdf

Last edited:

foggy

5 year old buck +

I would doubt that you will ever want for more power. Traction and weight is the shortcoming on most of these tractors.Tractor's already running 12+ psi boost. ;)

https://tractortestlab.unl.edu/c/do...3-4906-b6d1-19932c64eb52&groupId=4805395&.pdf

Jim Timber

5 year old buck +

Rear end is bigger on the 75hp version of my machine. I'm not turning the fuel up from where it is. Had I gotten the 45hp edition, I would've already cranked it up.

Jim Timber

5 year old buck +

Monday I rolled down to Eau Claire, WI to the Menards outlet/surplus store after seeing an ad for fork lift forks on craigslist. I was still recovering from my tree planting last week (knees hurt) so some windshield time in pursuit of a wild goose sounded nice. Why a goose chase you might ask? Have you ever watched a menards employee drive a fork truck? I didn't expect much out of their retired forks, but they were $99 + tax a pair per the ad and they had pallets full of them. I figured I could find something servicable, and I didn't know how right that hunch was until the very last set I looked at - Jackpot! :D

They're Cascade 2x5" class 3 and don't even have appreciable paint loss, let alone wear (and I'm talking about the bottoms).

Sure, they're severely overbuilt for my tractor, but it also means I won't bend them doing stupid things with them either.

Thought about how I wanted to make the carriage for a day and read up on the standards for mounting them, then drew up a print and material list and headed to the steel yard. 175# later, and I had my supplies.

I didn't document the build very well, so there's only a few progress shots.

Test fit of the tack welded assembly:

Paint booth :D :

And the last one is how I transported it under my atv:

My neighbor from Michigan is here now, so I'm keeping quiet until he proves unworthy of respect (which is possible yet), but for now there will be no midnight tractoring that isn't necessary. They're not here more than a handful of weeks over fishing season, so it's not a big deal. I'll find out how well I did on my very first SSQA mount tomorrow.

They're Cascade 2x5" class 3 and don't even have appreciable paint loss, let alone wear (and I'm talking about the bottoms).

Sure, they're severely overbuilt for my tractor, but it also means I won't bend them doing stupid things with them either.

Thought about how I wanted to make the carriage for a day and read up on the standards for mounting them, then drew up a print and material list and headed to the steel yard. 175# later, and I had my supplies.

I didn't document the build very well, so there's only a few progress shots.

Test fit of the tack welded assembly:

Paint booth :D :

And the last one is how I transported it under my atv:

My neighbor from Michigan is here now, so I'm keeping quiet until he proves unworthy of respect (which is possible yet), but for now there will be no midnight tractoring that isn't necessary. They're not here more than a handful of weeks over fishing season, so it's not a big deal. I'll find out how well I did on my very first SSQA mount tomorrow.

Jim Timber

5 year old buck +

Since I've got 3 buildings planned - Yes! :D

The grapple's great for moving logs and brush, but not very good at finished boards, or a pile of sheathing or drywall. How about a IBC tote full of maple sap? Or even just water...

Forks are super handy for moving "stuff." I know of several guys who palletize their snow blowers, lawn mowers, and even atv's to put them on racking for off season storage. That doesn't even scratch the surface on how many uses there are. ;)

The grapple's great for moving logs and brush, but not very good at finished boards, or a pile of sheathing or drywall. How about a IBC tote full of maple sap? Or even just water...

Forks are super handy for moving "stuff." I know of several guys who palletize their snow blowers, lawn mowers, and even atv's to put them on racking for off season storage. That doesn't even scratch the surface on how many uses there are. ;)

wiscwhip

5 year old buck +

Looks like a great find and a good build. That said, how thick are the walls on that tubing? It looks a bit thin in the pics. If they are too thin walled, That may be a trouble area if you get too much weight bouncing while driving on uneven ground. Keep an eye on that for your first few uses over rough ground. Then again, the smallest fork trucks I have ever driven were rated at well over 2 tons capacity, so those may be more than sturdy enough for your needs.;)

Jim Timber

5 year old buck +

The tubing is more than thick enough. The twisting torque on the forks translates into tension across the short dimension of the top tube and sheer in the vertical plane.

The top rail is 3/4x3". Even 1/4" looks thin next to it. The top tube and center supports are .120 wall. The bottom one is .083.

If you want to plug it into solidworks and do stress analysis, I'll give you the other dimensions. I'm not worried at all. The loader won't lift more than 4000# with full ballast at the pins.

The top rail is 3/4x3". Even 1/4" looks thin next to it. The top tube and center supports are .120 wall. The bottom one is .083.

If you want to plug it into solidworks and do stress analysis, I'll give you the other dimensions. I'm not worried at all. The loader won't lift more than 4000# with full ballast at the pins.

wiscwhip

5 year old buck +

I would think you would be good with the 1/8" wall, it isn't like you will be lifting items out on the tips of the forks like we do when loading large I-beams on to trucks where you need the added reach. I am just used to the heavy duty stuff we see in industrial settings, those carrier members would either be a solid casting or a solid section of 2" x 4" bar stock with the 3/4" bar welded to it solid with flux-core wire. Besides that, if you would have had the ends capped with the outer framing in that first pic, I wouldn't have questioned it at all.;) Overall, looks like a solid build and a hellava nice fab job! It sure is cool having the skills(and tools) to do that kind of stuff for yourself, I know I like having that abilty! ;):cool::D Just like anything, periodic inspection of the welds and structural members will keep you safe!;)

Jim Timber

5 year old buck +

I was cooking the joints when I welded the rails on. My spatter needed a cold chisel to remove (or flap wheel). I didn't want any chance of a cold lap, so I was up approaching globular transfer. This wasn't done with that little flux core thing I used on the vent - I was at home with my miller invision 354mp. :D Man, do I love welding with that power supply!

At 30.5" outside spread, the forks are 3" from the center supports. I don't think it'll twist, but time will tell. I'll try lifting the container with it when I move it up the hill in a couple weeks. I'm pretty sure the ass end will come up before there's any problems, but I will have empirical proof before doing anything risking human health. This ain't my first rodeo. :)

I'd almost taken a drive an hour the other direction to a fork truck bone yard to buy a carriage and forks, but the weight of those castings would've taken a big bite out of my useful capacity.

The rollback angle is a little disappointing, and this was a design element I struggled with. As you raise the boom, the angle increases, so I can't heel back a pallet at ground level like I would on a real fork truck (I have a lot of seat time on them - hundreds of hours), but I can pick the nose up first so it'll still work fine.

The ground isn't level here, so it looks even worse than it is.

That BBQ black doesn't slide for crap! I also can't grease them without collecting dirt. I guess a mallet is how it's going to be for adjusting width. :)

At 30.5" outside spread, the forks are 3" from the center supports. I don't think it'll twist, but time will tell. I'll try lifting the container with it when I move it up the hill in a couple weeks. I'm pretty sure the ass end will come up before there's any problems, but I will have empirical proof before doing anything risking human health. This ain't my first rodeo. :)

I'd almost taken a drive an hour the other direction to a fork truck bone yard to buy a carriage and forks, but the weight of those castings would've taken a big bite out of my useful capacity.

The rollback angle is a little disappointing, and this was a design element I struggled with. As you raise the boom, the angle increases, so I can't heel back a pallet at ground level like I would on a real fork truck (I have a lot of seat time on them - hundreds of hours), but I can pick the nose up first so it'll still work fine.

The ground isn't level here, so it looks even worse than it is.

That BBQ black doesn't slide for crap! I also can't grease them without collecting dirt. I guess a mallet is how it's going to be for adjusting width. :)

Last edited:

Jim Timber

5 year old buck +

That'd probably do the trick. :)

D

dipper

Guest

All I have is forks, none of those fancy grapples. they are on more than my bucket. They lift a lot of logs.

They are overkill, intended for a large skid steer. I modified them for my loader.

They are overkill, intended for a large skid steer. I modified them for my loader.

Jim Timber

5 year old buck +

Just moved a big brush pile with one bite in the grapple. I have a lot of respect for forks, but they're not the same tool as a grapple.

Jim Timber

5 year old buck +

I got a couple more goodies since the last time this was updated.

Wallenstein FX85 skidding winch:

Promptly pulled the decal off the back and replaced it with a SMV sticker. I also swapped out the chain sliders for midgets and got some cable chokers. Cable chokers are substantially lighter than G70 logging chain (even 5/16"), and it's a good system all the pro's use. I still have chains for skidding and other tasks, but I'm not going to use them on my winch line.

I also started putting my LED's on the tractor. The side lights are 18W floods and do a remarkable job illuminating everything forward of the rear wheels. I had bought some little strip LED lights with the intention of mounting them on the belly up by the front axle, but they weren't glass lenses as the listing claimed, and they were hot enough to burn you within 3 minutes of being powered on with a 15vdc 1.5A wall wart (which promptly died from the experience) - so I sent those back.

Wiring/switches are in place ready to put the front and rear aux lights on when I get around to it.

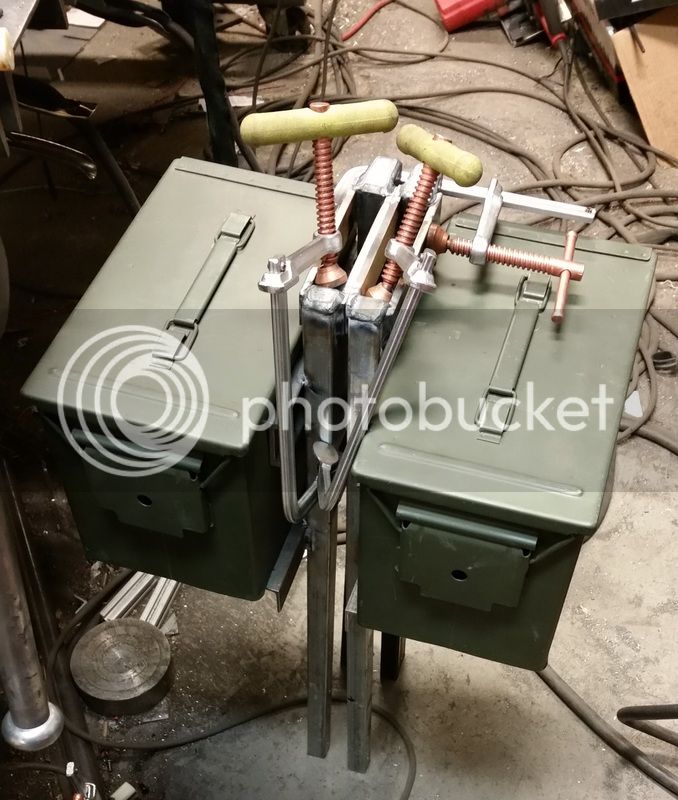

The winch didn't come with any provisions for storing chains, saws, wedges, mauls, or anything. So I took a bunch of measurements Sunday and started conjuring up some options. Then earlier today I started building a mirror set of mounts for ammo cans with integral chainsaw scabbards. I'm not sure if I'll be making plywood inserts for these or if I'll get fancy and get some UHMW to line them with. I need to find a cheap source for the 1/4" UHMW plate before I make that decision. These will take a 30" bar with ease. I run a 28" on my Jonsered 2188, so being able to swallow that much saw was a need. I left a little extra in case I just go with more of these clamp guards like I have on the 357xp in the photo. They're not bad to use and not all that expensive either. They also hold up better than the thin sleeves most saws come with.

The steel yard didn't have any short chunks of 1x1 11 or 14 gauge tubing, so I decided to use up some galvanized I had rather than buy a 24' stick or pay the $5 cut fee. It's been slow going as I've been welding and then leaving til the fumes clear, then going back and doing that routine again. Welding on zinc makes some nasty byproducts and can make you sick. Even with the exhaust fan going, it's not something I hang around. But other than slow, the mounts are turning out nice.

I've got a couple options for mounting them and will need to bring them to the winch to make the final choice. One way keeps the winch narrower, but raises the saws; and the other brings things down, but exposes the cans and saws more on the sides.

Wallenstein FX85 skidding winch:

Promptly pulled the decal off the back and replaced it with a SMV sticker. I also swapped out the chain sliders for midgets and got some cable chokers. Cable chokers are substantially lighter than G70 logging chain (even 5/16"), and it's a good system all the pro's use. I still have chains for skidding and other tasks, but I'm not going to use them on my winch line.

I also started putting my LED's on the tractor. The side lights are 18W floods and do a remarkable job illuminating everything forward of the rear wheels. I had bought some little strip LED lights with the intention of mounting them on the belly up by the front axle, but they weren't glass lenses as the listing claimed, and they were hot enough to burn you within 3 minutes of being powered on with a 15vdc 1.5A wall wart (which promptly died from the experience) - so I sent those back.

Wiring/switches are in place ready to put the front and rear aux lights on when I get around to it.

The winch didn't come with any provisions for storing chains, saws, wedges, mauls, or anything. So I took a bunch of measurements Sunday and started conjuring up some options. Then earlier today I started building a mirror set of mounts for ammo cans with integral chainsaw scabbards. I'm not sure if I'll be making plywood inserts for these or if I'll get fancy and get some UHMW to line them with. I need to find a cheap source for the 1/4" UHMW plate before I make that decision. These will take a 30" bar with ease. I run a 28" on my Jonsered 2188, so being able to swallow that much saw was a need. I left a little extra in case I just go with more of these clamp guards like I have on the 357xp in the photo. They're not bad to use and not all that expensive either. They also hold up better than the thin sleeves most saws come with.

The steel yard didn't have any short chunks of 1x1 11 or 14 gauge tubing, so I decided to use up some galvanized I had rather than buy a 24' stick or pay the $5 cut fee. It's been slow going as I've been welding and then leaving til the fumes clear, then going back and doing that routine again. Welding on zinc makes some nasty byproducts and can make you sick. Even with the exhaust fan going, it's not something I hang around. But other than slow, the mounts are turning out nice.

I've got a couple options for mounting them and will need to bring them to the winch to make the final choice. One way keeps the winch narrower, but raises the saws; and the other brings things down, but exposes the cans and saws more on the sides.

Jim Timber

5 year old buck +

I have the 4x4 square tube clamped to my bench because of the two different mounting options. If the bracket is on the floor, it's the wider position, and up on the channel is the narrower one. Just trying to see how the height differences will impact functionality in the field prior to getting up North.

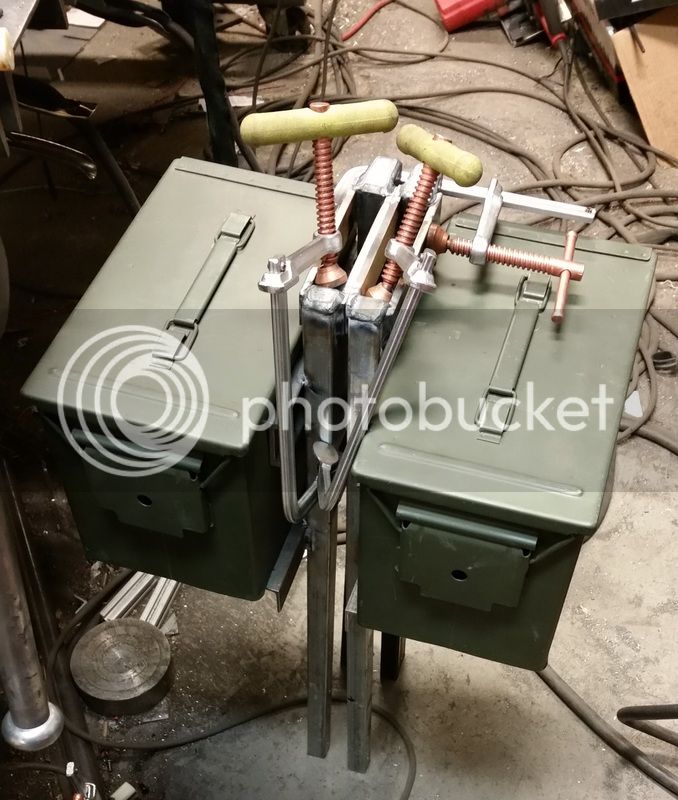

Both of them clamped together for easy porting to the truck. :)

I may add some baskets or some other types of storage to these, but I want to do a test fit on the winch before I move forward with anything else.

Both of them clamped together for easy porting to the truck. :)

I may add some baskets or some other types of storage to these, but I want to do a test fit on the winch before I move forward with anything else.

tooln

5 year old buck +

Jim

I'd go UHMW for the inserts. Have you ever used Badger Plastics?

http://badgerplastics.com/

Last time I ordered some for home I just went through McMaster-Carr.

I'd go UHMW for the inserts. Have you ever used Badger Plastics?

http://badgerplastics.com/

Last time I ordered some for home I just went through McMaster-Carr.

Jim Timber

5 year old buck +

There's an outfit in the Metro here who might have what I need in a scrap bin. I've got a note out to them on FB, but I'll probably have to call them when I get up. Their website is down at the moment.

Guys get a lot of use out of wood scabbards, but I agree, I want the plastic if it's reasonably priced.

Guys get a lot of use out of wood scabbards, but I agree, I want the plastic if it's reasonably priced.

Jim Timber

5 year old buck +

Not sure what postage would be on this, but it looks perfect for what I need.

http://www.ebay.com/itm/250-X-12-X-...stic-Polyethylene-Sheet-FDA-NSF-/261469010242

Now I have a price point to work off anyway. :)

http://www.ebay.com/itm/250-X-12-X-...stic-Polyethylene-Sheet-FDA-NSF-/261469010242

Now I have a price point to work off anyway. :)

Similar threads

- Replies

- 50

- Views

- 764

- Replies

- 8

- Views

- 405

- Replies

- 9

- Views

- 492