Wind Gypsy

5 year old buck +

Fab shop in progress...

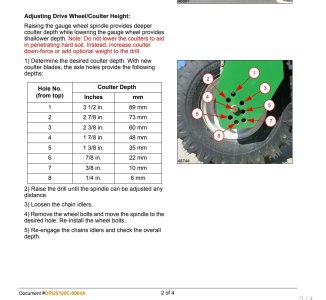

They don't stick out past the lights which is important. Small engineering error so one weight has to be inverted which shouldn't be a problem. Very happy with it. Tomorrow we drill.View attachment 67978View attachment 67980View attachment 67981View attachment 67982

Oooh! I like and I want. Nice work!

Last edited: