Foggy47

5 year old buck +

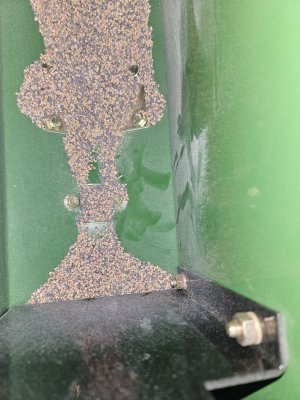

I have left all the springs and press wheels alone (press wheels are two notches from all the way forwrard). I simply adjusted that drive wheel to get the right depth and then use the top link to tweak it perfect. I use a level to check the drill from side to side and front to back. Then....I can see by movement of the hydraulic top link (with small tweaks) when the pressure is near neutral......and that works for me. Then, I watch the drive wheel to make certain it functions correctly.I set the t-handles to the third or fourth slot on the shallow end this year. Seemed to be about right.

How’d it go?

Edit to add, I leave all down pressure springs to factory settings. My logic being that if you set any to be stiffer, that reduces the down pressure available to all other rows and down pressure seems to be a limiting factor for me with these drills.

Ive tried to alter things a bit with the press wheel settings......but find the settings I have seem good. I do not find any variation in the depth wheel settings due to ground compaction variations.....as I have firm, sandy soil. Now, and further tweaking is done via the hydraulic top link (if any).