If you zoom in on the setup you can see a 9" torpedo level on the big seed box.

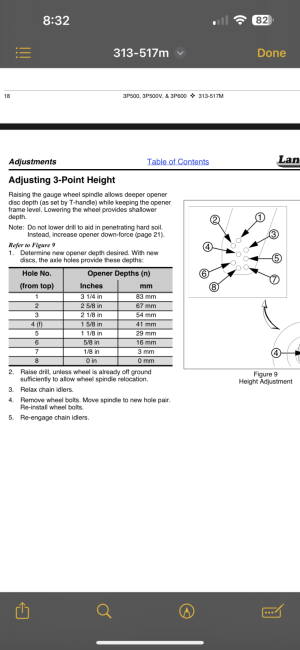

That being said, you are correct, it wasn't level. When I set the drill down with the 3 pt arms, when it was level I was getting inconsistent ground contact with the drive wheel. After playing around with the hydraulic top link, I couldn't find a happy medium very easily where the drill was level and still got consistent drive wheel contact. I believe this is because my ground is hard and the cutting wheels weren't penetrating. I'm not sure if this means I'm short on weight or I need to make some other adjustments, open to ideas on this?

I feel like an extra 400 lbs of weight could help the cutting wheels get a little deeper but also there are likely some other settings I should play with.