A lot (or all) of it is in the bullet shape and throat. Some bullets don't like a jump in to the rifling, others do, and some just don't do well regardless.

I haven't tried all there is, but so far Barnes 130's have been fantastic in 6.5 prc. The ELD-X 140 is used in the reference load for the B-14, but I struggled to get sub-moa out of them. Just good enough I can't say it doesn't. I think the whole experience with buying the gun kinda ruined it for me and I just can't get it to chasing small groups with it.

In the 1980's I bought a used Ruger 77 Varmint Rifle in 22-250 for my first "real" accuracy gun.....which was soon followed with a Ruger 77 in 243 and a Ruger 77 in 223. And so started my experience with accuracy and prairie dog shooting.

I had a friend with some custom built rilfles that were based on the Remington 700 action.....and is known as a better starting platform for accuracy than the Rugers.....which I did not know at the time.

Anyway....I realized his guns were far superior to mine.....and aat that point we were alllusing the cheapest components to reload that we could find. For our 223 rounds we could get them reloaded for about 12 cents / round. 5 cents for a bullet (Remington Core locks, 1cent for a prmer and the rest on powder from Hogden (J.B. Hogeden is a good friend of mine to this day).

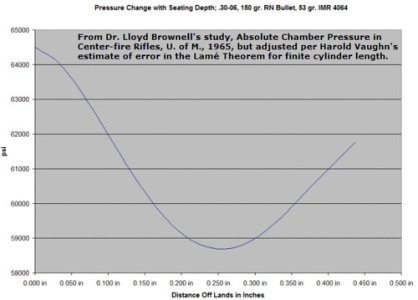

At first my freinds loads were far better than mine.....as he had better guns. But I discovered that getting my bullets seated out....close to the rifling.....were getting far better results than his custom guns could provide. And so, my quest for better handleds began.

I cannot tell you how many hours I spent in those days "candeling" bulletls to get some soot on the bullet so I could later interpret the precise seating depth needed to get better accuracy. This soot method was the best available a that time.

So.....I finally decided there had to be a better way......and spent an entire winter in my basement to find a better solution to bullet seating depth for center fire rilfes. Lol. I spent allot of hours to figure out a tool that could provide the needed function.

The result is still in production today....as the Hornaday Lock and Load OAL Gauge...which I invented int eat 1980's. More refinements over time with the bullet comparator and headspace gauges and more. The first lathe I bought to make modified cases cost me $1000.....and I had to re-build it to get it to work....and covert it to single phase power too. I had next to NO money to do this.....but followed through on my dream.

My biz started on $5000 cash and that was it. Bought a few extrusion dies and a few lbs of material......which almost killed my budget....and made a few products. Not sure how I was lucky enough to sell some stuff.....but each small sale at gun shows helped to fuel my fire. Soon I was at the NRA Nationals to see if I could sell this thing.....and they ate it up. Next....was a call on my friend at Sinclair International whom immediately gave me a big order.. Still not huge business......but over time I was able to find some confidence and quit my day job. I though my wife would kill me that day. lol.

And ...that my freinds is how you make better accuracy.....Still works......lol. Man...the stories I could tell............