Wind Gypsy

5 year old buck +

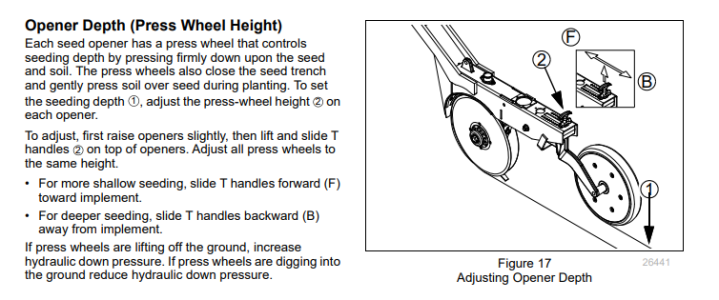

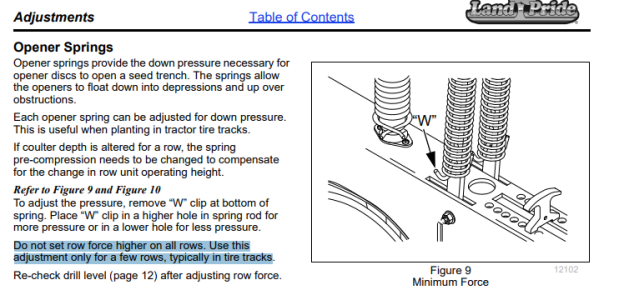

Before thinking about forces at play in depth, I increased the "down pressure" settings on every row on my esch thinking it might get everything to depth easier - the drill performed worse. Then I read that user manual and it advised against doing that. The different rates are really just to be able to allocate more of the drills total weight on certain rows in your tire tracks. I wouldn't be surprised if @Brian662's drill worked better if he set the 2 rows in the tire tracks back to the factory setting so more down pressure was available to the 7 other rows.