SD51555

5 year old buck +

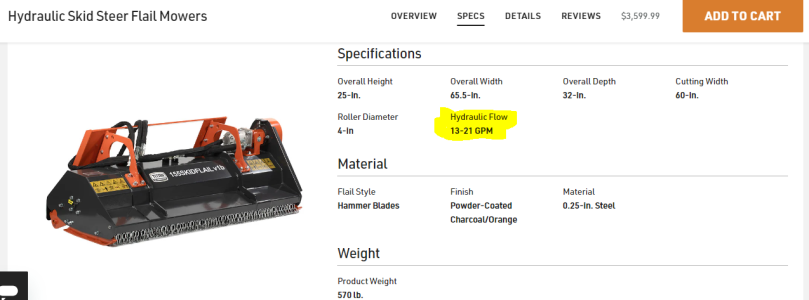

Alright gang, new idea on the table. My brother has a Cat 246C skid steer. I've verified this machine has the hydraulic output to run this mower, and the 68" mower will pretty much cover the tracks. Might have to cheat over one way a few inches just in case.

Anyway, this is a significantly more affordable hydraulic flail mower than the very few other options I saw on the web. Can any of you machinery guys pick apart why this might be either a poor quality machine, or a lighter duty machine? For my purposes, this will not be a demolition mower that will hit stumps and rocks and 3" oak trees. This will be for smooth land high volume cover crop or canary grass mowing at most. This would be a cadillac mower for my purposes, but my brother may be able to get some side work to help buy down the cost of this mower.

What do you think of this?

palletforks.com

palletforks.com

Anyway, this is a significantly more affordable hydraulic flail mower than the very few other options I saw on the web. Can any of you machinery guys pick apart why this might be either a poor quality machine, or a lighter duty machine? For my purposes, this will not be a demolition mower that will hit stumps and rocks and 3" oak trees. This will be for smooth land high volume cover crop or canary grass mowing at most. This would be a cadillac mower for my purposes, but my brother may be able to get some side work to help buy down the cost of this mower.

What do you think of this?

Hydraulic Skid Steer Flail Mower Attachment | Titan Attachments

The Hydraulic Skid Steer Flail Mower is ready to help you maintain your land at a wallet-friendly price.