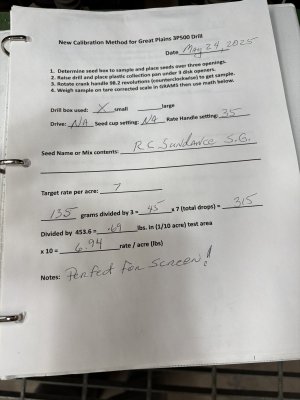

Got my drill hooked up today and calibrated perfect on the first shot. The drill is level, and ready to roll....maybe tomorrow. Used the drill settings for alfalfa....and come in almost on the nose (that work sheet show an old method I used at one point. Disregard as I the math is not right for this method).

Also FINALLY found the "real estate" to mount my seed rate manual on the side of the drill. That should be a handy spot for it.....tired of searching for it every time I need it. My foam marker pump and reservoir takes up the spot that GP used for that manual box.

Also show my (4) weights mounted on the sides of the drill with Z brackets I had made for my drill. I think those weights add 240 lbs to the drill. Add the extra step / walk board....and I think I am all done with mods for this year. Pics below.

The last pic shows the alternate hole location from the 3 point lift cylinders to the tractor drag links. My drill was hard to lift high enough to place it on the rolling cart I have. So by choosing these pin locations my drill can be lifted about 8" higher than the past.....and my drag links can still drop into the dirt if I want to. Much more versatile for my needs. OH....and one great mod to my tractor sway bars is that I bought SS Pins from MacMaster Carr that have little ball detents in the pins. This way I can just pull them and insert with one hand in no time flat. Huge frustration saver and cheap solution.

Also replaced the junk affair that GP furnishes with the drill for the drag link connections on the drill. I had lost these pins on several occasions and was lucky I did not tweak the drill. Who would put hairpins on the "inside" of the pin locations where they are bound to come out. May better show that mod one day.....as it is one that really irks me. Had to do the same thing on my roller crimper. DUMB engineering.

View attachment 77752View attachment 77753View attachment 77754