browndog

5 year old buck +

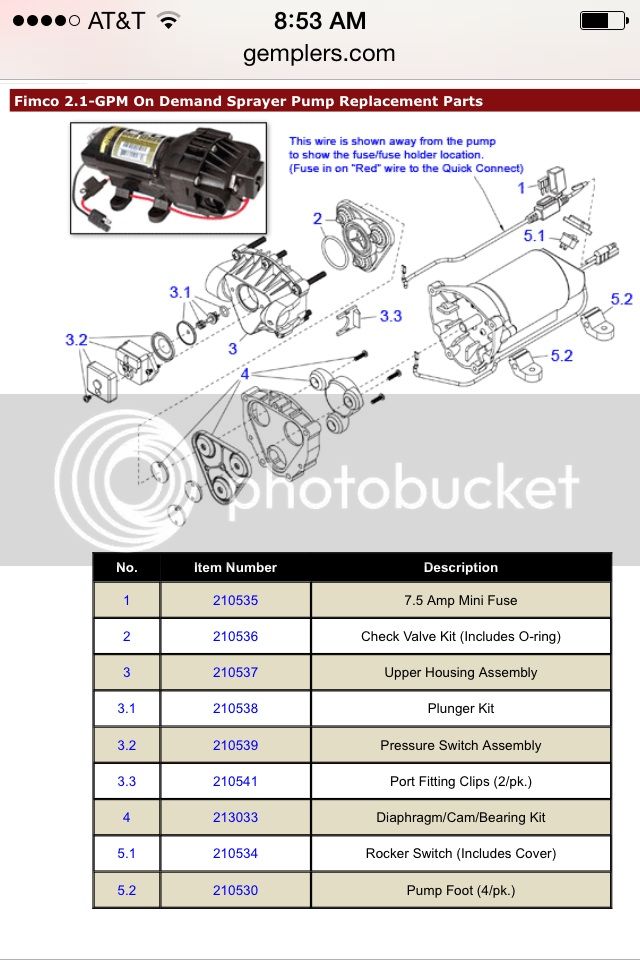

I have the ATV 25 gallon sprayer with boom and I think the pump is on its' way out. It's the original 2.1 gpm pump that came with the sprayer and it's about 10 years old. I'm thinking about replacing the 2.1 gpm pump with the 3.8 gpm pump. I think the bolt holes will line up and was wondering if the 3.8 gallon pump would be alright? Would there be any problems with the boom nozzles with me using the 3.8 pump?