-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

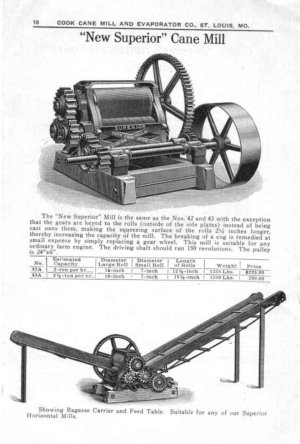

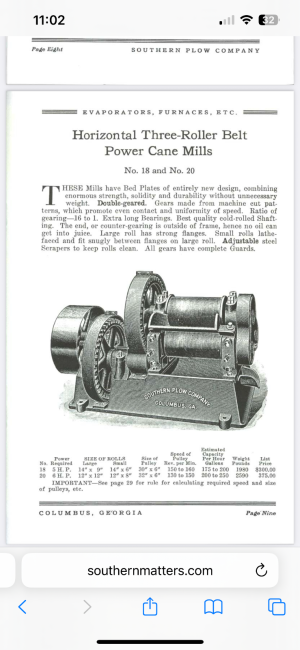

Bought a Sorghum Mill

- Thread starter b116757

- Start date

rocksnstumps

5 year old buck +

Maybe you can get a lead on something like the yesterdaystractors.com forum. Or not sure if there is a forum or webpage on thresheree/old sawmill clubs that go beyond local in your area. Gotta cast a big net. Stuff like that has unfortunately been snatched up by the scrappers and turned into toaster ovens.

Edit: or perhaps you can try to contact these guys flywheel-supply.com. Probably have to send an email as you can go to their menu and select pulleys and it brings up pics and prices for a bunch of old flat belt pulleys but no good way of searching for sizes.

Edit: or perhaps you can try to contact these guys flywheel-supply.com. Probably have to send an email as you can go to their menu and select pulleys and it brings up pics and prices for a bunch of old flat belt pulleys but no good way of searching for sizes.

Last edited:

Jerry-B-WI

5 year old buck +

What was your solution for bearings?

b116757

5 year old buck +

I recast the babbit bearings using lead free babbitWhat was your solution for bearings?

Jerry-B-WI

5 year old buck +

Did you have the bearings bored or did you shim the shafts for clearance? Did you put oil grooves in the bearings?I recast the babbit bearings using lead free babbit

Jerry-B-WI

5 year old buck +

I'm curious what the sprocket is for on the second drive shaft.

b116757

5 year old buck +

Outfeed conveyorI'm curious what the sprocket is for on the second drive shaft.

b116757

5 year old buck +

No boring and oil grooves I did shim the shafts to get the clearance I wanted and my bearing halves fit very tightly in the housing for the main roller.Did you have the bearings bored or did you shim the shafts for clearance? Did you put oil grooves in the bearings?

Last edited:

b116757

5 year old buck +

One of the drums is broken loose from the shaft had been brazed sometime in the past and that repair has failed dropped it off at the guys place I work with for a little machine shop magic. I’d just as soon he turn a small steel insert to go between the shaft and drum ends and I can braze them together that would remove the stress from the simple braze repair that was done in the past.

Attachments

Last edited:

Jerry-B-WI

5 year old buck +

Can that gear be turned180* and be remounted? Do you need the side plates on it? Boston Gear may have something in stock.

Similar threads

- Replies

- 7

- Views

- 590