Well, I hope to work on the bed winch project for the Pioneer 700 this weekend. This was inspired by the SB Woods bed winch. Here is a video of an install on a Pioneer 1000:

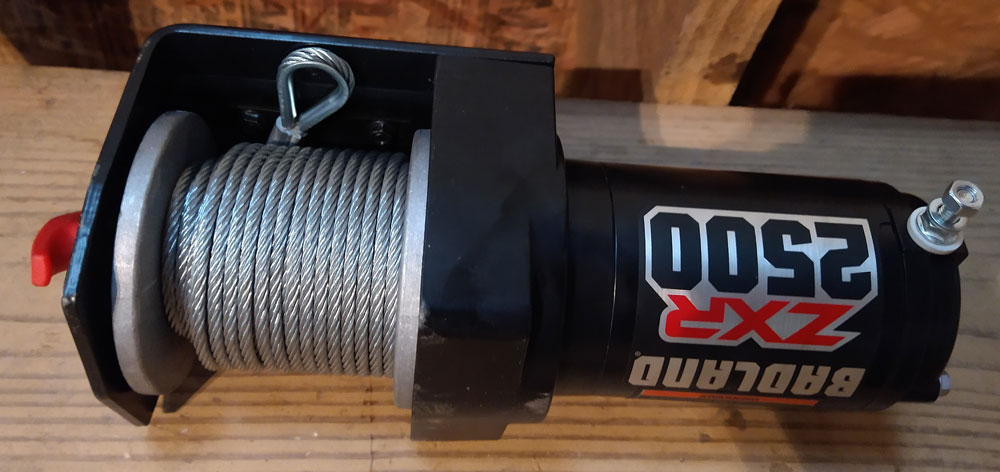

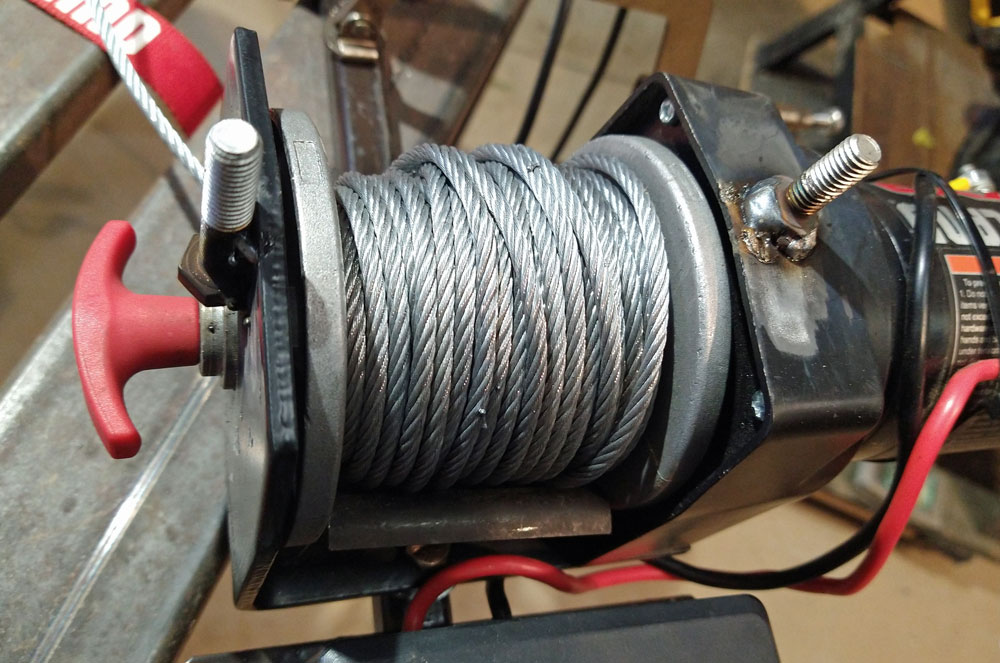

I considered buying one from them, but I got a welder last winter and I thought this might be a good opportunity for a tiny DIY welding project for me. So, I bought the Winch from Harbor Freight with a coupon. Here is what I got:

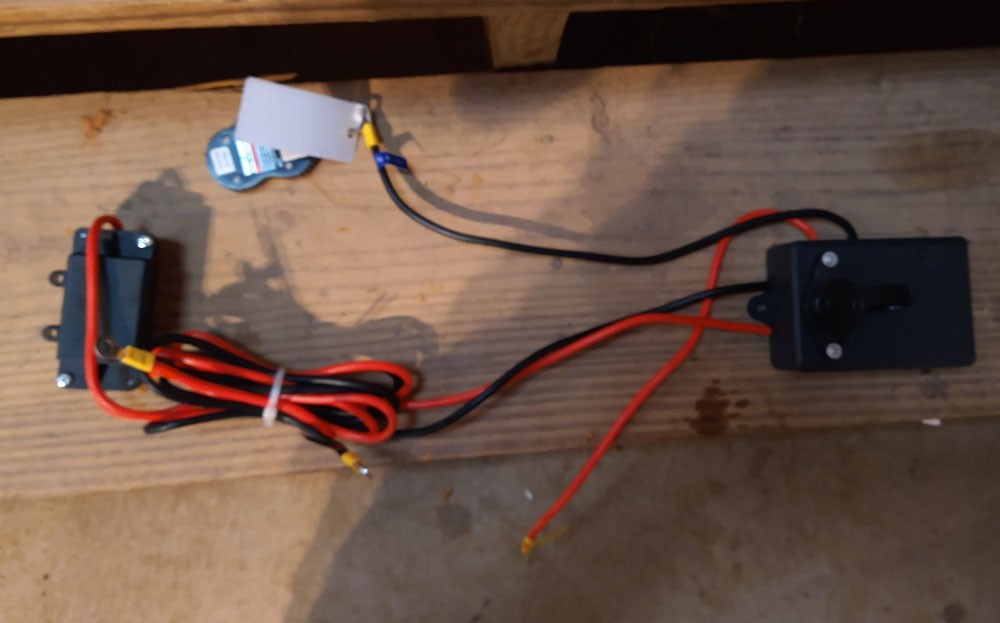

Plug-in for tethered control and in-line fuse

Tethered control

Remote

This all came as part of the winch package.

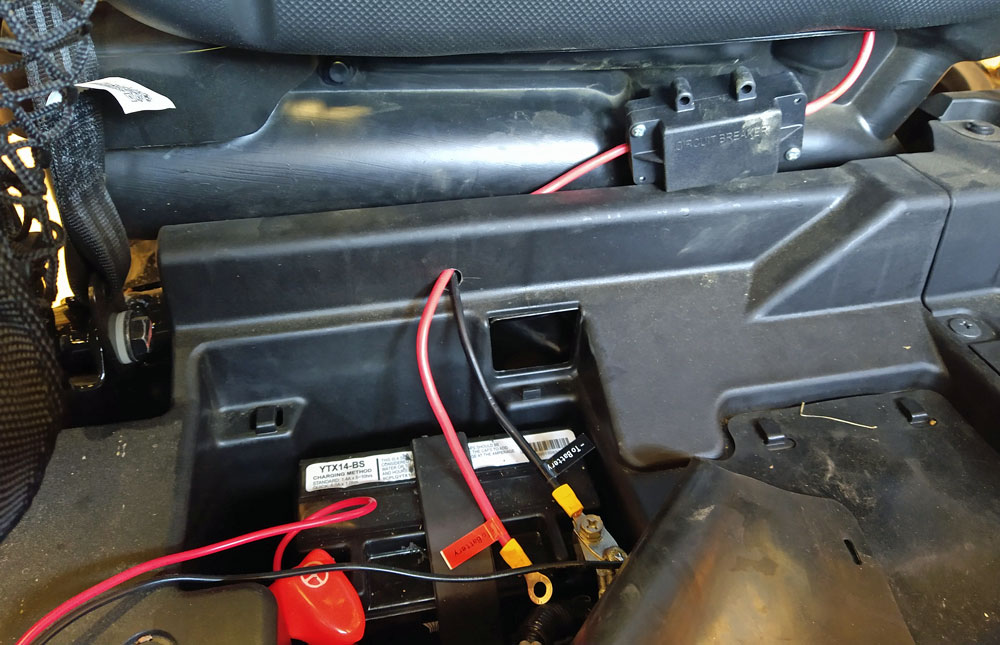

I then bought these connectors so I can unplug the winch when I'm not using it:

https://www.amazon.com/gp/product/B014FEV6EU/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1

I also bought the same light used with their version (bottom of this page):

https://www.sbwoodandweld.com/shop

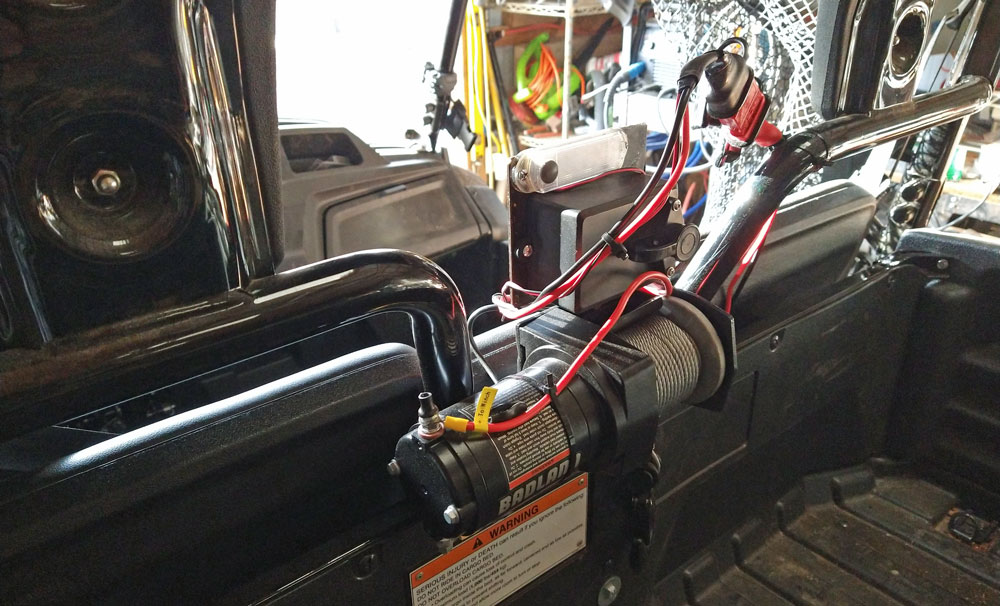

I had planned to build my own bracket. Rather than using their approach, I decided to make a telescoping square tubing bracket from mild steel I bought a piece of 12" x1" x 1/8" tubing and a piece of 14"x3/4"x1/8" square tubing as raw materials. I also picked up some scrap while I was at MetalSupermarket.

I'll try to take some pictures of that this weekend.

With my first dry fit attempt, I did not like how much the winch itself protruded into the bed of the UTV. My 700 is a little different than the pioneer 1000. I found that by orienting the winch 90 degrees, it fit much better with my bed. This does mean that instead of shearing across the bolts, the force will be directly against the threads. Also , with 3/4" square tubing less 1/4" for the wall thickness leaves only 1/2" of metal. That is not much margin if I use 5/16" bolts, so I'm considering using grade 8 1/4" -28 fine thread bolts for attaching the winch to the 3/4" tubing directly. The winch should be operating well below its capacity simply lifting deer into the bed so I don't think this should be an issue.

I'll update as things progress.

Thanks,

Jack