yoderjac

5 year old buck +

Stumbled across this article while researching improving soil for growing trees..

Most of the data is way over my head, but take home for me is biosolids are an effective means of improving soil for increased tree growth compared to compost, mulching, and other soil enhancement methods. I started applying milorganite to my container oaks and top dressing around oaks in my yard this summer primarily b/c it seemed like a "safe play" with more upside than risk if I got carried away and overdid it..... Seems like milorganite was effective for both my container trees and oaks I had spaded and transplanted around my home...

Hoping DGallow will translate this articles data for me (us) when he has time!

http://www.isa-arbor.com/events/conf...nbroch_eta.pdf

That was one of the articles I read when I started looking into biochar. I found it very interesting. Last month I noticed a tree crew working on one of neighbors trees. I asked the crew to dump the chipped debris in my back yard.

I have a line on used 55 gal drums I can use to make a kiln. All I need now is time...which ain't gonna happen during hunting season...

Thanks,

Jack

Jack, always appreciate your comments! Good grab on the free wood chips. I'd like to reach out to a tree trimming operation to see if I could provide them a free spot to dump their waste.

I'll be very interested if future research supports this published studies findings for both Biosolid (BS) and Biochar (BC) affecting tree growth performance. I'm floored there's only one article regarding BS available on the Reforestation, Nurseries, and Genetic Research website. There's a grand total of 5 BC article on RNGR website which I assume is a result of the it being such a new development in the science world.

Regardless, BS makes a lot of intuitive sense to me despite the fact that the "professional tree growing" community doesn't seem as intrigued at the poo option as I am. I'm on the fence at the sensibility of BC as it relates to its true value from an ROI perspective as it relates to time and equipment required. I guess if I'm going to roll the dice at this stage of the game, I'll take my chances with a $15 bag of milorganite vs building a kiln and trucking in wood chips to make BC.

^^^should be able to get milorganite for $6-$8 if you watch the sales at big box stores.

Is there 'life' in milorganite?

Is there life in biosolids?

Is there aerobic life in fresh fungal compost?

Biochar is lifeless...sterilized by pyrolysis....but provides structure for future soil life....mix something living (fresh fungal compost) with biochar....then you have something to enhance soil quality, soil life, and tree growth.

Does your soil already have good structure to ample depth? Answer that before using char....first question to answer.

What types of soil life are missing in your soil?....the second question to answer IMO....land management history and current plant community dynamics provide good clues.....microscopy of soil provides a more detailed answer.

+

Good read, great way to recycle waste to help amend the soil.

Well, I finally found the time to make a TLUD Kiln. I'm lit it up for the first time today. The wood chips were wet, so I'm not sure how well it will work, but the purpose of this first burn is to season the unit and burn off any paint or chemical residue left in the drums.

Thanks,

Jack

Well, things didn't work out great. I knew I was going to have an issue because my wood chips were wet. I wasn't quite sure what effect that would have. The kiln didn't get hot enough to deal with the wet chips.

The initial top light went well. When I added the top section with chimney things seemed to work as expected. When I checked it an hour later, things had cooled down quite a bit and I could see the chips weren't being consumed. I added more top fire and put the top back on. It heated up again. Several hours later I checked it.

The paint had burned off the top section. The barrel was still hot at the fire line but it was not raging. Only the top 6 inches of chips were consumed. My guess is that it will die over night. I'll check it in the morning and see what happened.

Worst case, I'll try drying the chips and starting again. I'm guessing that with the wet chips, I'll need a real hot fire and I think the wetness is inhibiting some of the updraft.

Thanks,

Jack

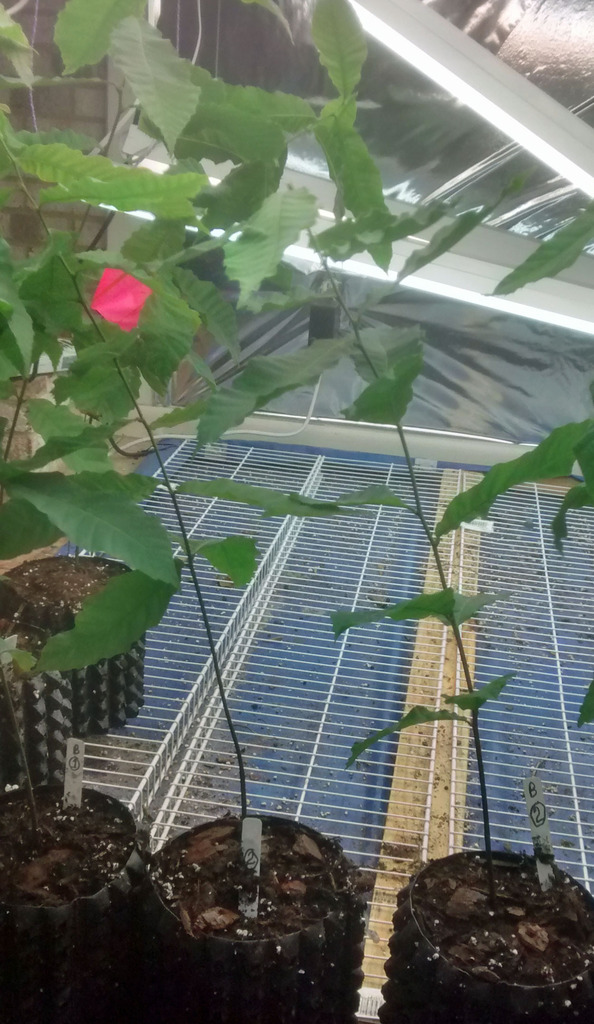

Unexpectedly things worked better than I thought. This morning I checked the unit. I expected to see it half burned at best. Instead, I found it had all burned down. Here is the resulting bichar produced:

There was not much, but I attribute that to the fact that the material was wet and allowed to burn so long. I think if the chips were dry and I snuffed out the fire after about an hour or so I would have ended up with much more. I'm happy with what I got.

I decided to try another burn with the wet chips. This time I took some pictures as I loaded it. My first step was to turn the cement blocks on their sides. I think the solid tops were blocking too many of the holes on the bottom of the can reducing the updraft. I then loaded it with more chips:

I then added some paper, cardboard, and wood scraps from the garage to get some coals started on top.

I then fired it back up. While I let the top fire get going, I used the FEL to spread some chips out on the ground. I'm hoping they will dry in the sun before I burn my next load.

One interesting note. If you look at the original picture of the kiln from the previous post, you will see the afterburner is blue. The first burn got it hot enough to burn off the paint, but it was not hot enough to burn the paint off the middle of the barrel section.

Thanks,

Jack

Biosolids should provide a little microbial action in the soil. The nutrients will be slowly available so you are most likely not going to see an immediate reaction to a treatment. It isnt really organic but has some of the same benefits.Some people think it has heavy metals, possibly pathogens and is a source of high phosphorus in ground water. lately we have been seeing it used as a filler in fertilizer blends because it can be cheaper than limestone and is more beneficial.

If it's available I prefer poultry manure. It can be OMRI certified as a true organic and it would not have the perceived risks of Biosolids and they are basically the same cost per ton.

I have a saying I like to use when trying to sell the Poultry against Biosolids.

"Do you know the difference between Houactinite and Milorganite? Milorganite is higher in cheese and beer, Houactinite Is higher in jalapeno." (INTERNAL IMAGE LIKE EMOTICON REMOVED)

Last edited: