yoderjac

5 year old buck +

Many years ago, soon after I started processing my own deer, I started to acquire processing tools. My first vacuum seal machine was one of the inexpensive, bag outside the machine, models. There were several things I didn't like about this design and the quality of the first unit I got. The design requires the use of special bags that have channels in them. While the machines are inexpensive, the bags are not. The cost is negligible for occasional use. The biggest problem with this design is liquid. Any liquid gets sucked to the mouth of the bag preventing a good seal. The low end unit I original got did not last long. It wasn't long before it could not suck out enough air.

As I started processing more deer each year, we bought a high end model of the same design. It lasted about 3 times as long, but had all the same design issues. We tried putting paper towels between the meat and the mouth of the bag. It worked ok, but was a slow PITA. Eventually, we learn to put the meat in the freezer directly on trays for a couple hours. We would not let it freeze, but aa it got close, the moisture evaporated. This worked pretty well, but we still had the expensive bag issue. When that unit died, I decided to step up to a low end chamber model.

I got a VP112 which is the lowest end chamber model I could find. Chamber models work completely differently. The entire bag goes inside a chamber in the machine. The machine evacuates the air from the entire chamber, both inside and outside the bag. The machine then seals the bag before letting air back into the chamber. When it does, the bag is sucked into the meat as the pressure outside the bag is much greater than the pressure inside it. Because of the way it works, liquid is not sucked out the bag opening. In fact, you can even vacuum seal soup with this type of machine.

The VP112 worked pretty well at first. It worked as advertised. The bags are a fraction of the cost of channel bags. It also sped up the process. It took just as long to evacuate the chamber as it took the external bag models to evacuate a bag. However, the sealing bar is 12" so we could seal two 6" wide bags at once. It wasn't long before the plastic lid cracked. It simply could not handle the pressure. I was able to use plastic epoxy to fix the crack and get it working again. We ordered a new lid, but just left it sit in the box since it was working fine. After several years, we noticed in the last year or so that it just wasn't evacuating enough air and we were getting a little freezer burn. Also, I noticed that I had to increase the seal time and occasionally I would have to reseal bags.

So, we ordered a new seal bar to see if that was the issue. We processed a deer the other day. I replaced the seal bar and tested the unit to make sure there was not a leak on the external port. (This unit has an external port that you can use to vacuum special canisters but we rarely use that). It was clearly the chamber that was leaking. I presumed it was the lid not sealing with the rubber gasket around the chamber. So, I installed the new lid. No luck. I noticed the new lid said VP112S. I looked it up on the internet and found that because of the lid cracking and leaks, they redesigned the VP112 to VP112S shortly after we bought the machine. I compared the lids and although the both fit in general, the new lid had thicker plastic. I can only assume that they increased the width of the rubber gasket on the redesign, because I could not get a seal with the new lid. I went back to the old lid. I could eventually get enough seal, but no matter how much I set the seal time for, the motor could simply not evacuate the chamber enough. It worked, but no better than it had been.

Well, I'm getting too old for this aggravation. So, I decided to order a commercial grade unit. They are expensive, but life is short.

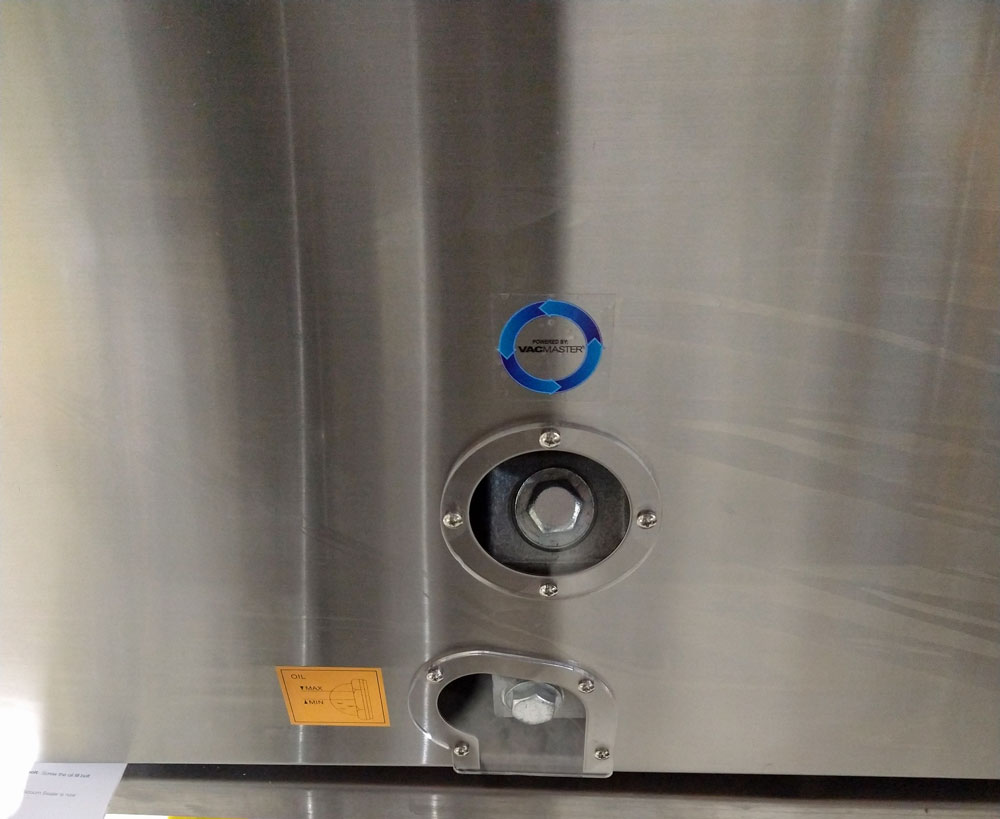

I ordered a VP321. The general design is the same, but there are several differences. First, it has 1.5 hp oil filled pump vs. the dry piston pump on the 112. It has two 17 1/4" double wire seal bars vs. the 12" single wire seal bar on the 112. The cycle time is 20-40 sec vs 30-60 sec for the 112. The lid design is completely different. I've seen no reports of lid or sealing issues with this commercial model. Finally, this beast is 200 lbs vs the 50 lb 112. At least on paper, this should significantly reduce our processing time. The second and larger seal bar should cut our time at least in half plus any gains from the shorter cycle time.

When the unit arrives and I get it setup I'll take some pics and report back. Then, presuming I shoot another deer, I'll report after first use.

Thanks,

Jack

As I started processing more deer each year, we bought a high end model of the same design. It lasted about 3 times as long, but had all the same design issues. We tried putting paper towels between the meat and the mouth of the bag. It worked ok, but was a slow PITA. Eventually, we learn to put the meat in the freezer directly on trays for a couple hours. We would not let it freeze, but aa it got close, the moisture evaporated. This worked pretty well, but we still had the expensive bag issue. When that unit died, I decided to step up to a low end chamber model.

I got a VP112 which is the lowest end chamber model I could find. Chamber models work completely differently. The entire bag goes inside a chamber in the machine. The machine evacuates the air from the entire chamber, both inside and outside the bag. The machine then seals the bag before letting air back into the chamber. When it does, the bag is sucked into the meat as the pressure outside the bag is much greater than the pressure inside it. Because of the way it works, liquid is not sucked out the bag opening. In fact, you can even vacuum seal soup with this type of machine.

The VP112 worked pretty well at first. It worked as advertised. The bags are a fraction of the cost of channel bags. It also sped up the process. It took just as long to evacuate the chamber as it took the external bag models to evacuate a bag. However, the sealing bar is 12" so we could seal two 6" wide bags at once. It wasn't long before the plastic lid cracked. It simply could not handle the pressure. I was able to use plastic epoxy to fix the crack and get it working again. We ordered a new lid, but just left it sit in the box since it was working fine. After several years, we noticed in the last year or so that it just wasn't evacuating enough air and we were getting a little freezer burn. Also, I noticed that I had to increase the seal time and occasionally I would have to reseal bags.

So, we ordered a new seal bar to see if that was the issue. We processed a deer the other day. I replaced the seal bar and tested the unit to make sure there was not a leak on the external port. (This unit has an external port that you can use to vacuum special canisters but we rarely use that). It was clearly the chamber that was leaking. I presumed it was the lid not sealing with the rubber gasket around the chamber. So, I installed the new lid. No luck. I noticed the new lid said VP112S. I looked it up on the internet and found that because of the lid cracking and leaks, they redesigned the VP112 to VP112S shortly after we bought the machine. I compared the lids and although the both fit in general, the new lid had thicker plastic. I can only assume that they increased the width of the rubber gasket on the redesign, because I could not get a seal with the new lid. I went back to the old lid. I could eventually get enough seal, but no matter how much I set the seal time for, the motor could simply not evacuate the chamber enough. It worked, but no better than it had been.

Well, I'm getting too old for this aggravation. So, I decided to order a commercial grade unit. They are expensive, but life is short.

I ordered a VP321. The general design is the same, but there are several differences. First, it has 1.5 hp oil filled pump vs. the dry piston pump on the 112. It has two 17 1/4" double wire seal bars vs. the 12" single wire seal bar on the 112. The cycle time is 20-40 sec vs 30-60 sec for the 112. The lid design is completely different. I've seen no reports of lid or sealing issues with this commercial model. Finally, this beast is 200 lbs vs the 50 lb 112. At least on paper, this should significantly reduce our processing time. The second and larger seal bar should cut our time at least in half plus any gains from the shorter cycle time.

When the unit arrives and I get it setup I'll take some pics and report back. Then, presuming I shoot another deer, I'll report after first use.

Thanks,

Jack