-

If you are posting pictures, and they aren't posting in the correct orientation, please flush your browser cache and try again.

Edge

Safari/iOS

Chrome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bill's knife build

- Thread starter tooln

- Start date

tooln

5 year old buck +

I don't use a color chart, I just watch for a cherry red and most importantly getting the entire blade non magnetic. I have yet to have a blade fail any of my test. I temper @ 450 for 2.5 hours. One thing I found to be very important is to let the blade cool to air temp in the oven slowly. After the 2.5 hours I turn the oven off and just walk away for at least 5 hours.Tooln, thanks for adding the videos. very helpful in learning the process.

What color chart do you use to conform proper heat treat based on steel type?

What temp do you temper at for how long?

tooln

5 year old buck +

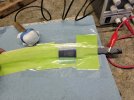

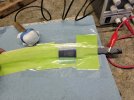

Today I etched my logo into the blade for Bill's knife. Electrochemical etching in short is an electrical and chemical reaction that removes metal. I make a vinyl stencil and put it on the blade and then tape off the rest of the blade to protect it from the etching solution. I use a DC power supply, I made a applicator that I cover with a cotton pad. After the etch is done I have to neutralize any left over solution so it doesn't stain the blade. I then use a nylon/brass bristle brush to clean the etched area. I then apply a coloring solution to the etch and sand/polish it smooth.

tooln

5 year old buck +

Just a little FYI for anyone following this build/thread. Normally a knife build from start to shipping is a week or less. This one is a little different for many reasons. Bill is in no hurry as he won't be Tuna fishing for a while. With the holidays and covid many of my plans were pushed back during the holiday season but taking place now as well as a few Dr. appointments. Then the sub zero temps lately it doesn't pay to heat the garage for an hour or 2 of work. Tomorrow I've finally have no appointments so I can dedicate several hours to Bill's knife. Stay tuned.

Bill

Administrator

For sure no hurry. I’ll only get to look at it until June.Just a little FYI for anyone following this build/thread. Normally a knife build from start to shipping is a week or less. This one is a little different for many reasons. Bill is in no hurry as he won't be Tuna fishing for a while. With the holidays and covid many of my plans were pushed back during the holiday season but taking place now as well as a few Dr. appointments. Then the sub zero temps lately it doesn't pay to heat the garage for an hour or 2 of work. Tomorrow I've finally have no appointments so I can dedicate several hours to Bill's knife. Stay tuned.

Tree Spud

5 year old buck +

Just a little FYI for anyone following this build/thread. Normally a knife build from start to shipping is a week or less. This one is a little different for many reasons. Bill is in no hurry as he won't be Tuna fishing for a while. With the holidays and covid many of my plans were pushed back during the holiday season but taking place now as well as a few Dr. appointments. Then the sub zero temps lately it doesn't pay to heat the garage for an hour or 2 of work. Tomorrow I've finally have no appointments so I can dedicate several hours to Bill's knife. Stay tuned.

Quality takes time, measure twice cut once

tooln

5 year old buck +

I've made more than 2 dozen knives. In that I've had 2 different handle scales that got trashed because I messed up the pin holes. One blade I missed a spot when etching and the blade etched where it shouldn't have, so I started over on that one. Later I ground out the bad etch area re beveled and all was fine. Luckily this was a 3/16" blade not a 1/8 so I had material to work with. I also had a few pieces of leather that I had to start over on because of cutting the wrong side up. All the leather was reusable for stacks or straps. A bad blade will not leave my shop I also refuse to use inferior materials.Quality takes time, measure twice cut once

tooln

5 year old buck +

Today I did a little work on the handle. I also did an edge retention test. The purpose of the test is to make sure it retains an edge. It also test the handle strength. Once the knife is near completion I stop posting pics as I want the new owner to be the first to see the completed knife.

Buckly

5 year old buck +

Sharp is sharp and that knife looks sharp. Keeping the edge is a must so I like your attention to this detail. I’ve had knives that are completely dull after one or two uses. On the other hand I’ve had some Cutco steak knives that are still almost as sharp as when I got them that have been in contact with a lot of bone and porcelain and everything else under the sun I cut with them and it’s been almost 15 years With no sharpening. Always admired that.

tooln

5 year old buck +

That's why I do the test I do so the end user knows exactly what he/she is getting.Sharp is sharp and that knife looks sharp. Keeping the edge is a must so I like your attention to this detail. I’ve had knives that are completely dull after one or two uses. On the other hand I’ve had some Cutco steak knives that are still almost as sharp as when I got them that have been in contact with a lot of bone and porcelain and everything else under the sun I cut with them and it’s been almost 15 years With no sharpening. Always admired that.

Bill

Administrator

Once the knife is near completion I stop posting pics as I want the new owner to be the first to see the completed knife.

Don’t have to hold off on my account. I don’t mind sharing unless it’s a policy.

tooln

5 year old buck +

It's just something I do. I feel the person who's getting the knife should be the first to see the completed knife. After you get it I'll gladly post the finished pics or you can.Don’t have to hold off on my account. I don’t mind sharing unless it’s a policy.

Bill

Administrator

Sheath is done, certainly not my best sewing job.

Edit. The more I think about it I'm going to make a new sheath. I'm not happy with this one.

You asked me what I wanted the sheath to be. My idea was fine but just go with artistic judgement. (Kinda like the whole build) Make it the way you think it should be.

I tell my taxidermist that to. He nails it more often then not.

tooln

5 year old buck +

I didn't like the way the stitching turned out. I also made a few very slight changes in the design/shape that will make me happy. Chances are you would never noticed the design/shape changes but I know they are there. If I'm not happy with the way something turns out I wouldn't expect the customer to be happy either.

Similar threads

- Replies

- 25

- Views

- 3K

- Replies

- 66

- Views

- 9K