I’m thinking of drilling in some purple tops. I want to use the small box for the first time. Only thing in the book is rape and only for the main seed box at rates too heavy. I’d like to drill around 4 pounds per acre. The 3 point makes it very difficult to calibrate simply no room. Any body have an idea where to start? I’m thinking around setting 25 or so.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Time to drill some turnips. 3p606nt

- Thread starter momatt

- Start date

Potter co notill

5 year old buck +

If you want to calibrate u do it before you hook it up to the tractor on the 3pt model

Yes going by my notes you should be close at 25

I use 37 for 5lb radish and 3lb PTT

Yes going by my notes you should be close at 25

I use 37 for 5lb radish and 3lb PTT

Potter co notill

5 year old buck +

Yes my deer eat them all after we get a snow

Foggy47

5 year old buck +

I've never had a problem with spiders (yet) but I've blown through my tubes with an air hose when I got my machine. Wonder about a bristle brush on a 2' long twisted wire section.....like I have seen somewhare. I just cannot remember where.....lol. One good reason to spin your seed drive and make sure you have seeds dropping at every opener.......IMO.I read the other thread and decided to calibrate. Setting 25 was throwing about 3.6 lbs. little spiders sure made a mess with their webs in the drop tubes. Anyone figure out a good way to clean those? Also those wire clips were clearly designed by the devil himself.

Foggy47

5 year old buck +

Edit: Just remembered "bottle brush". $10. via amazon. ref=sr_1_4_sspaI've never had a problem with spiders (yet) but I've blown through my tubes with an air hose when I got my machine. Wonder about a bristle brush on a 2' long twisted wire section.....like I have seen somewhare. I just cannot remember where.....lol. One good reason to spin your seed drive and make sure you have seeds dropping at every opener.......IMO.

Thanks. Have you ever had trouble with the drive wheel not making contact? I have to keep my top link pretty short to keep that wheel hitting the ground. Seems like the press wheels are not pushing down. I had the depth adjusted all the way shalllow probably not an issue planting deeper.

Potter co notill

5 year old buck +

Planting with the small seed box the press wheels don’t matter the seed is falling after the opener, the press wheel controls the opener. Do you have your drive wheel in bottom hole? You want the drill level when planting not tilted down like it sounds like you have it. If your ground is hard it will be harder for your drive wheel to touch. I started out all the way down but now as I’ve been no tilling for 7yrs the soil has gotten softer so I moved it up and helps getting more depth.

Nightvision

5 year old buck +

For spider problems, you can get a chemical called Tempo. Spray it where you have big problems. Problems will be gone.

swat1018

5 year old buck +

Thanks. Have you ever had trouble with the drive wheel not making contact? I have to keep my top link pretty short to keep that wheel hitting the ground. Seems like the press wheels are not pushing down. I had the depth adjusted all the way shalllow probably not an issue planting deeper.

I did when my drill was new. Drop the drill run 5 or 10', and put a level on the large seed box lid. Level the drill. If your drive wheel skips, then move the drive wheel axle down a hole or two. I did this once and have never had a problem since.

That’s what I am gonna do. ThanksI did when my drill was new. Drop the drill run 5 or 10', and put a level on the large seed box lid. Level the drill. If your drive wheel skips, then move the drive wheel axle down a hole or two. I did this once and have never had a problem since.

TreeDaddy

5 year old buck +

I had to do this^^^^^That’s what I am gonna do. Thanks

Will be making my second no till planting this fall

Maiden voyage spring '22 a technical success but plots fried up in drought

bill

Bill

Administrator

I read the other thread and decided to calibrate. Setting 25 was throwing about 3.6 lbs. little spiders sure made a mess with their webs in the drop tubes. Anyone figure out a good way to clean those? Also those wire clips were clearly designed by the devil himself.

What speed was that in? Mines a pull type so I have a speed setting and a seed setting. The speed setting operates the agitator in the seed box and or the gear that drops seed in the big box, I believe.

I like to take my hoses off when not in use, but like you, hated trying to put the wire clamps back on.... I got one of these and it makes it much easier....I read the other thread and decided to calibrate. Setting 25 was throwing about 3.6 lbs. little spiders sure made a mess with their webs in the drop tubes. Anyone figure out a good way to clean those? Also those wire clips were clearly designed by the devil himself.

Wire Clamp Pliers

omicron1792

5 year old buck +

I just ordered some now! Thanks.I like to take my hoses off when not in use, but like you, hated trying to put the wire clamps back on.... I got one of these and it makes it much easier....

Wire Clamp Pliers

Those spiders get in mine too and block the small seed tubes. Messing with the hose clamps was the hardest part.

Wild Thing

5 year old buck +

I like to take my hoses off when not in use, but like you, hated trying to put the wire clamps back on.... I got one of these and it makes it much easier....

Wire Clamp Pliers

LOL - I used to disconnect 3 of the hoses to calibrate my drill but as we all know it is a royal PITA get the wire rings back on. I finally found out that I could easily catch the seed in small pails for calibrating, without disconnecting the hoses so I have not taken them off in years. My drill stays in the barn so the rubber isn't being damaged when it isn't in use. No need to ever take them off.

Never had the tube blockage issue before...but sure enough, while I was planting this year I noticed one of my small box tubes was blocked. I suppose it could have been spiders? Don't really know. Anyway I had to take the tube off to clean it out, and again I experienced the PITA getting the wire hose clamps back on. I will be ordering a pair of those pliers soon in case it ever happens again.

Wild Thing

5 year old buck +

I’m thinking of drilling in some purple tops. I want to use the small box for the first time. Only thing in the book is rape and only for the main seed box at rates too heavy. I’d like to drill around 4 pounds per acre. The 3 point makes it very difficult to calibrate simply no room. Any body have an idea where to start? I’m thinking around setting 25 or so.

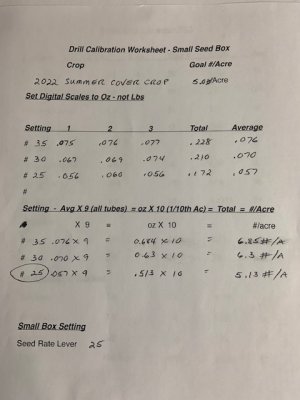

I have a pull type LP 606NT momatt so I have never had any drive wheel issues and can not speak to that. Unlike a lot of you guys, I do calibrate my drill when I need to figure out settings for new seeds or mixes. I have done it enough now that I can go by previous years' settings, or at least have a good starting point from notes of previous years. My brassica mix this year was Winfred Forage Brassica and PTT at 2#/acre and Rape, Crimson and Balsana clovers at 1#/acre each. Setting #25 gave me 5.13#/acre which I used in my summer cover crop mix, but I upped it to 6.85#/acre (Setting #35) for my July brassica planting.

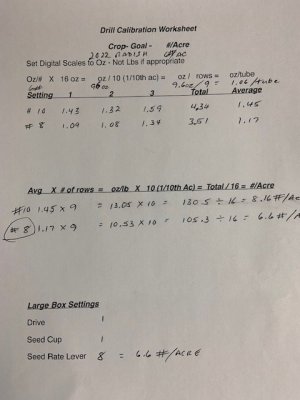

I know I can get by with including the forage radish with the smaller seeds in the small seed box, but I prefer to plant my radish a little deeper so I plant radish from the large box - and yes, it can be done very accurately...

Drive Gear 1 - Seed Cup 1 and Seed Rate Lever setting #8 gives my a little over 6#/acre of forage radish.

4-5 weeks after planting the brassica/clover mix, I broadcast rye over the brassicas so I don't have bare dirt in the spring. This has worked out real well for me here.

Similar threads

- Replies

- 15

- Views

- 769