IkemanTx

5 year old buck +

Posted here so i didn’t further hijack the AA thread.

I blew out my ankle this year just before my season started and haven’t been able to swap batteries or pull cards on any cameras.

Most cameras will be dead (or memory cards full) by now, as i run video mode on everything and the batteries have been running since may.

Losing a hunting season sucks, but what is really eating me up is losing an entire year worth of intel from not being able to do my early season battery/card swap…. So since i’ve been stuck at home for weeks I decided to work on fixing the problem.

I found a video on YouTube last year from “The Handy Hunter” where he put together a small diy solar battery. The battery he uses for that build is no longer available, so my son and i soldered one up ourselves out of 3,000mah rechargeable AA batteries.

Then, we assembled the solar panel / battery according to his video (soldering and shrink tubing instead of wire nuts).

Most of my brownings will accept EXTREMELY large SD card sizes, so with these panels / batteries supplying permanent power i should be able to get videos for a full year without fail when paired with a 256 gig card. (Assuming the camera isn’t on a high traffic spot like a feeder) in picture mode with a memory card that big, this thing could probably run continuously for a couple of years before filling the card.

The 12v regulators i picked up are running a little lower than 12v, but the camera still runs just fine off of it. But, i wish i had tested that part before soldering and assembling.

I only run 2 cameras on private land, though, and this setup is definitely not something i want to have on public land. Theres too much money and time invested in it, and i think you would be able to spot it from a mile away regardless of how good a sponge paint job is. I originally planned to do some 12v lithium battery packs that i can charge at home and just hang behind the camera for public land,

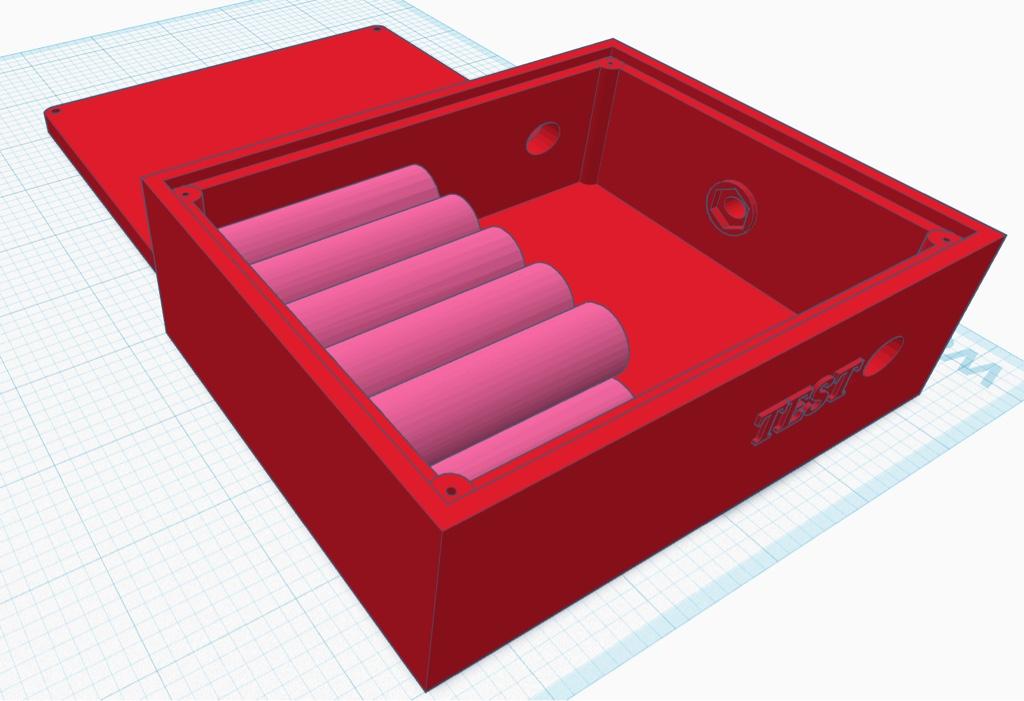

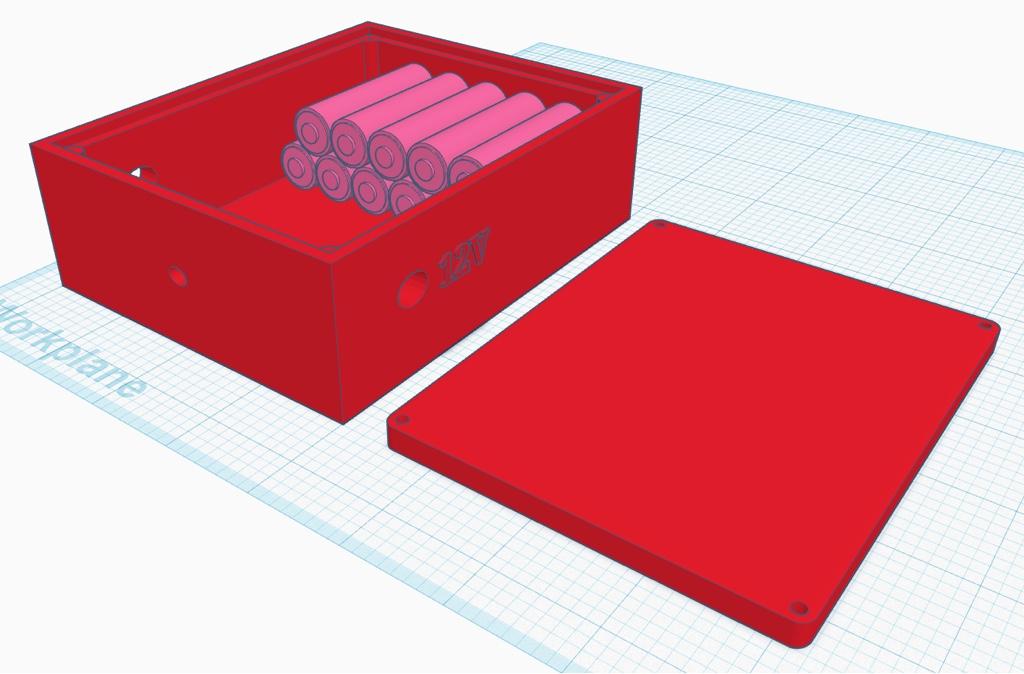

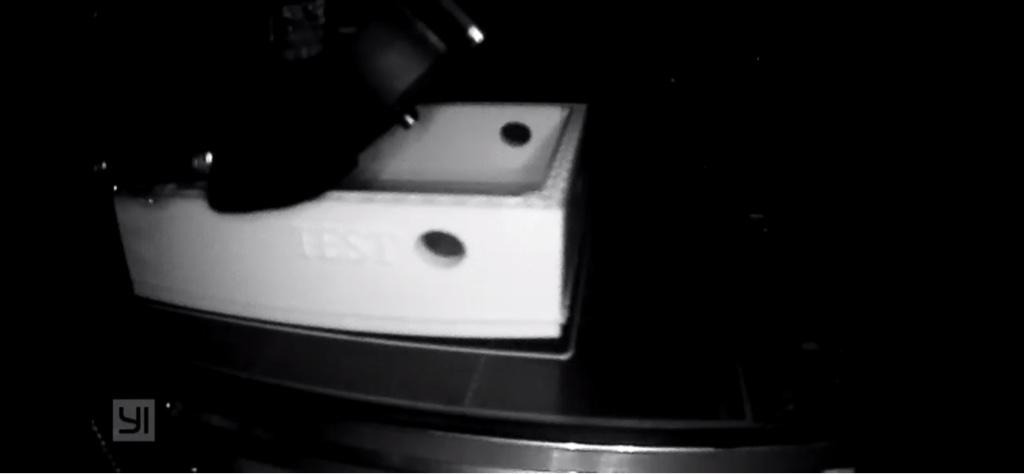

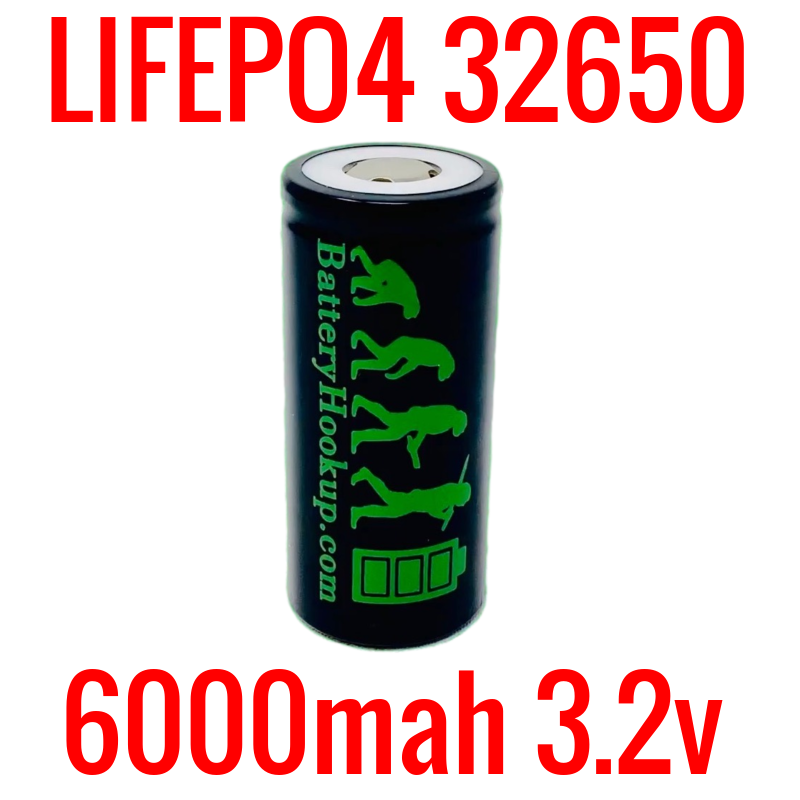

but i found a much smaller 12v solar panel, that runs 1.5 watts as opposed to this MUCH bigger panel’s 1.8 watts. That got me down a rabbit hole of just how small and ergonomic i could make something like this.

Sent from my iPhone using Tapatalk

I blew out my ankle this year just before my season started and haven’t been able to swap batteries or pull cards on any cameras.

Most cameras will be dead (or memory cards full) by now, as i run video mode on everything and the batteries have been running since may.

Losing a hunting season sucks, but what is really eating me up is losing an entire year worth of intel from not being able to do my early season battery/card swap…. So since i’ve been stuck at home for weeks I decided to work on fixing the problem.

I found a video on YouTube last year from “The Handy Hunter” where he put together a small diy solar battery. The battery he uses for that build is no longer available, so my son and i soldered one up ourselves out of 3,000mah rechargeable AA batteries.

Then, we assembled the solar panel / battery according to his video (soldering and shrink tubing instead of wire nuts).

Most of my brownings will accept EXTREMELY large SD card sizes, so with these panels / batteries supplying permanent power i should be able to get videos for a full year without fail when paired with a 256 gig card. (Assuming the camera isn’t on a high traffic spot like a feeder) in picture mode with a memory card that big, this thing could probably run continuously for a couple of years before filling the card.

The 12v regulators i picked up are running a little lower than 12v, but the camera still runs just fine off of it. But, i wish i had tested that part before soldering and assembling.

I only run 2 cameras on private land, though, and this setup is definitely not something i want to have on public land. Theres too much money and time invested in it, and i think you would be able to spot it from a mile away regardless of how good a sponge paint job is. I originally planned to do some 12v lithium battery packs that i can charge at home and just hang behind the camera for public land,

but i found a much smaller 12v solar panel, that runs 1.5 watts as opposed to this MUCH bigger panel’s 1.8 watts. That got me down a rabbit hole of just how small and ergonomic i could make something like this.

Sent from my iPhone using Tapatalk