Foggy47

5 year old buck +

I'm snake bit. I had a few issues early on with my (new to me) used Great Plains Drill....but I thought I found the problems (seed lever was not installed correctly and I was turning the calibration handle the wrong way, etc.). Never had these kinda problems calibrating my Tar River Saya drill.....and I got to the desired rate(s) quite quickly. Not so on this drill. This should not be rocket science......and I wonder how I could be so far off?......repeatably.

Today I spent a good part of the day weighing and bagging the seeds I want to drill (and broadcast within the next week). In my big seed box I plan to put out 112 lbs of winter rye and 5 lbs of radish......thus totaling 117 lbs. In the small seed box I have a mix of 4# Med Red clover, 1 # Alice White Clover, 4# Yellow Sweet Clover, 4# Chicory.....for a total of 13# in the small box.

I calibrated the small seed box first. And from the charts in the manual set the seed handle on the small box to 65 which should have put out 13 lbs or there about. But I was putting out 42 lbs / acre. WHOA. Recalibrated two more times and got the rate at 13.5 # with the handle set on 22. Could not understand the discrepancy.....but went with it.

Then calibrated the large box and had to reduce the handle setting again by 1/2 of where I started. Strange .....but went out to try it on one acre. Watched the depth setting and all seemed good in that department....could see seed being delivered between the coulters (used a small flashlight) and kept an eye on the drive wheel......and never saw it not moving. All seemed to operate correctly.

Got done with that acre.....and had 80% + of the seed remaining in the small box (weighted it out) and perhaps 25% of the seed in the big box remaining. I did not have time to empty and take an absolute wieght on the big box.....but I think my estimate is fairly close.

It appears the initial output using the 65 setting on the handle may have put out the right rate after all.......but it sure did not calibrate that way.....not even close.

Re-did my calibration math tonight.....and had a look at my worksheets again. I cannot find where I am going wrong. I'm stymied. Very frustrated with this product right now.

The only thing I can think of is to get someone else to drive my tractor and for me to walk along and watch the drill operation. (drive chains and seed cups, drive wheel etc.). Any ideas to get me in the right direction??

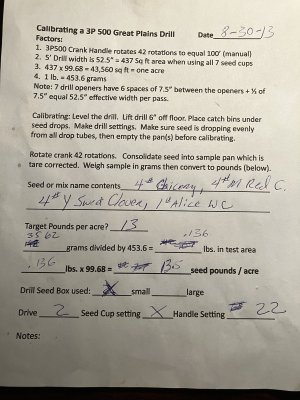

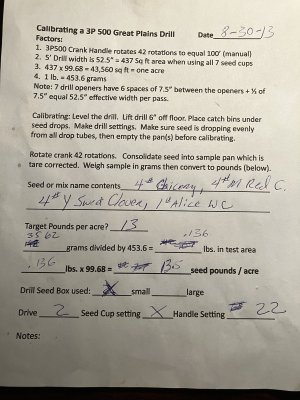

Here is my worksheet on the small seed box. (The year should read 8-30-23 - my bad.)

Today I spent a good part of the day weighing and bagging the seeds I want to drill (and broadcast within the next week). In my big seed box I plan to put out 112 lbs of winter rye and 5 lbs of radish......thus totaling 117 lbs. In the small seed box I have a mix of 4# Med Red clover, 1 # Alice White Clover, 4# Yellow Sweet Clover, 4# Chicory.....for a total of 13# in the small box.

I calibrated the small seed box first. And from the charts in the manual set the seed handle on the small box to 65 which should have put out 13 lbs or there about. But I was putting out 42 lbs / acre. WHOA. Recalibrated two more times and got the rate at 13.5 # with the handle set on 22. Could not understand the discrepancy.....but went with it.

Then calibrated the large box and had to reduce the handle setting again by 1/2 of where I started. Strange .....but went out to try it on one acre. Watched the depth setting and all seemed good in that department....could see seed being delivered between the coulters (used a small flashlight) and kept an eye on the drive wheel......and never saw it not moving. All seemed to operate correctly.

Got done with that acre.....and had 80% + of the seed remaining in the small box (weighted it out) and perhaps 25% of the seed in the big box remaining. I did not have time to empty and take an absolute wieght on the big box.....but I think my estimate is fairly close.

It appears the initial output using the 65 setting on the handle may have put out the right rate after all.......but it sure did not calibrate that way.....not even close.

Re-did my calibration math tonight.....and had a look at my worksheets again. I cannot find where I am going wrong. I'm stymied. Very frustrated with this product right now.

The only thing I can think of is to get someone else to drive my tractor and for me to walk along and watch the drill operation. (drive chains and seed cups, drive wheel etc.). Any ideas to get me in the right direction??

Here is my worksheet on the small seed box. (The year should read 8-30-23 - my bad.)